TIG welding plays a significant role in fabricating different custom parts from several workpieces. In this process, welders use a special electrode in a protective gas to carefully join metals together. Many experts choose TIG welding because it joins metals accurately.

Moreover, TIG welding can work with many materials, like stainless steel and aluminum. Keep reading this article to learn more about how TIG welding works, its advantages and disadvantages, and how it compares to MIG welding.

What Is TIG Welding?

Tungsten Inert Gas (TIG) welding is a technique known for accurately joining metals. TIG uses tungsten electrodes to make a hot arc for melting metal, unlike usual welding.

What makes TIG welding special is how well it controls the heat. With a handheld torch and a shielding gas, usually argon, welders can carefully regulate the welding atmosphere, guaranteeing a process that is clean and free of contaminants. The non-consumable tungsten electrode generates the arc, melting the metal surfaces with a focus and finesse that sets TIG welding apart.

A filler material might be added to strengthen the weld in certain situations. TIG welding is applicable in industries with high standards, like aerospace and automotive, where precision remains crucial.

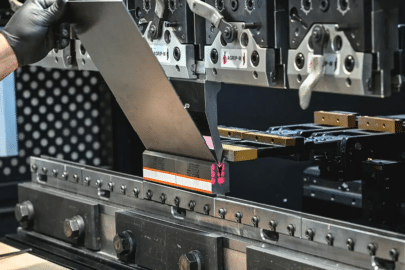

The TIG Welding Process

Every stage in the TIG welding procedure plays a role in establishing its standing as a technique that blends precision with flexibility. This renders the welding method a fundamental component in areas where quality and accuracy are indispensable. Comprehending the complexities of TIG welding entails exploring its stepwise process.

Let’s examine the TIG welding technique to enhance understanding:

Arc Formation

TIG welding starts by generating an electric arc. The tungsten electrode, selected for its elevated melting point, remains intact throughout the process. This non-consumable electrode is held in a handheld torch, serving as a precise instrument to generate the arc. The arc’s energy is directed to the metal surfaces, initiating the welding process.

Protective Shielding

It remains pivotal to ensure a clean and controlled environment in TIG welding. A stream of inert gas, commonly argon, surrounds the welding area. This shielding gas serves a dual purpose. Primarily, it hinders atmospheric components, like oxygen and nitrogen, from degrading the weld. Furthermore, it helps in maintaining the stability of the arc.

Metal Fusion

The generated arc produces intense heat, causing the metal surfaces to melt. This controlled melting is a hallmark of TIG welding, allowing precision in joining even the most intricate components. The welder can modulate the heat, ensuring optimal conditions for fusing the metals.

Filler Rod Application (Optional)

Depending on the project’s needs, welders might incorporate a filler rod into the liquefied pool. This additional substance, frequently composed of the identical metal as the workpiece, improves the strength of the weld. The TIG welder carefully adds the filler rod as needed, contributing to the strength of the joint.

Weld Solidification

While the melted metal undergoes cooling, it experiences solidification, resulting in a durable weld. The regulated characteristic of TIG welding reduces distortion and generates a neat, visually satisfying outcome. This feature is notably beneficial when the weld’s functional and visual elements are essential.

What Materials Are Compatible with TIG Welding?

TIG welding provides extensive compatibility with various materials. Even so, understanding how to TIG weld each sheet metal material involves considerations such as appropriate shielding gases, filler materials, and electrode selection.

Here are different materials compatible with TIG welding and their considerations:

Stainless Steel

TIG welding is notably suitable for stainless steel. This method seamlessly connects stainless steel parts, making it a preferred choice in industries that value corrosion resistance. TIG welding ensures quality welds in stainless steel applications.

Aluminum

Aluminum TIG welding gives a seamless interaction. The method’s controlled heat input allows the welding of thin aluminum sections without burn-through. However, TIG welding aluminum demands attention to cleanliness, appropriate filler materials, and skillful technique. The resulting welds exhibit excellent strength and aesthetics.

Carbon Steel

Welding TIG’s material compatibility extends to carbon steel. Whether in structural applications or inventive creations, TIG welding provides the control needed for precise and aesthetically pleasing welds in carbon steel. The process is particularly advantageous when welding thin sections.

Titanium

TIG welding is suited for the challenging properties of titanium. Its capacity to join exotic materials such as titanium accurately and without introducing impurities establishes it as a fundamental method in industries needing lightweight, high-strength components.

Copper and Copper Alloys

TIG welding also expands its adaptability to copper and its alloys. The controlled heat input of TIG welding minimizes the risk of thermal distortion in copper components. As a result, this welding method is employed in situations where conductivity and corrosion resistance remain critical.

Nickel Alloys

Nickel alloys offer high-temperature strength and corrosion resistance. They also find suitable compatibility with TIG welding. This method’s ability to maintain the characteristics of nickel alloys during welding ensures quality joints in aerospace and petrochemical applications.

Advantages and Disadvantages of TIG Welding

TIG welding has its own set of pros and cons in sheet metal fabrication. It’s best to know when TIG welding is the go-to choice and when it might have limitations.

Check the pros and cons of TIG welding below:

Advantages of TIF Welding

Precision and Cleanliness

TIG welding stands out in applications that require precision. Welders using TIG can finely manage the heat input, leading to tidy and visually attractive welds. This accuracy is beneficial in industries where the appearance of welds is as vital as their structural make-up.

Versatility with Materials

TIG welding is compatible with various materials, including stainless steel, aluminum, and superalloys. This flexibility positions it as a favored option in industries where engineers might need to engage with diverse materials.

No Flux or Filler Splatter

Unlike some welding methods, TIG welding does not generate flux or filler splatter during the process. This contributes to a cleaner work environment and reduces the need for extensive post-weld cleanup. Hence, the absence of splatter enhances the overall efficiency of the welding process.

Defined Control over Heat Input

TIG welding provides welders with precise control over the heat input when welding. This control level is critical when working on thin materials or intricate designs. This, in turn, ensures that the base metal’s properties remain intact.

Aesthetic Appeal

Besides ensuring structural integrity, TIG welding is praised for its visual appeal. The meticulous control over the welding process allows the fabrication of welds with a polished appearance. This makes TIG welding well-suited for projects where aesthetics are a top priority.

Disadvantages of TIG Welding

Slow Welding Speed

TIG welding is generally slower than some welding methods like MIG welding. Though the thorough control over the welding process, including filler rod manipulation, makes it precise, it contributes to this slower speed. Therefore, TIG welding may be less suitable for high-production projects.

Limited Penetration on Thick Materials

In some cases, TIG welding may fail to penetrate thicker materials deeply. In these instances, alternative methods such as MIG or stick welding could be more appropriate for effectively connecting thicker sections.

Complexity and Skill Requirement

TIG welding requires more expertise compared to some other welding methods. For instance, the complex control for handling the welding torch and filler rod requires a skilled and experienced welder. This makes it challenging for beginners to use.

Sensitive to Contaminants

Contaminants like dirt, grease, or rust on metal surfaces can disrupt TIG welding. Hence, it’s best to ensure the workpieces are thoroughly cleaned and prepared for the best weld quality. This entails handling and preparing the materials with extra care.

Equipment Cost

The equipment for TIG welding, including the welding machine and gas supply, can incur high costs compared to other welding methods. As a result, this initial investment for TIG welding might be a challenge for smaller workshops.

Tungsten Electrode Fragility

The tungsten electrode can become brittle and prone to breakage if mishandled. Further, welders must exercise caution in choosing, grinding, and handling the electrode to avoid any disruptions in the welding process.

Applications of TIG Welding

TIG welding’s precise technique has become a staple across many industries today. It meets the detailed needs of the aerospace industry and also ensures the strength of automotive components and custom parts for industrial machinery. This makes TIG welding a valuable technique when fabricating strong and quality metal joints.

Here are some specific applications of TIG welding:

Aerospace Industry

Welding with TIG takes center stage in aerospace applications. For instance, TIG welding ensures the fabrication of components like aircraft frames, engine parts, and other critical structural elements. The method’s capability to handle lightweight materials, like aluminum and titanium, remains vital in this industry.

Automotive Fabrication

Automakers use TIG welding when fabricating automotive parts that require strength and a polished appearance. This welding technique remains ideal for high-quality welds like exhaust systems, roll cages, and intricate bodywork. The precision of TIG welding ensures the welded joints can withstand harsh conditions while using a vehicle and maintain a sleek finish.

High-Purity Welding in the Semiconductor Industry

The semiconductor industry demands exceptionally pure welds, and TIG welding meets this need. As such, TIG welding helps produce high-purity components for semiconductor production. Moreover, its ability to work with exotic alloys supports the stringent requirements of semiconductor fabrication.

Nuclear Power Plant

TIG welding also applies in constructing nuclear power plants. It produces solid and corrosion-resistant welds in nickel alloys and stainless steel, ensuring the pivotal parts can handle extreme conditions. So, using TIG welding helps ensure the reliability of the critical systems within nuclear facilities.

Petrochemical Industry

TIG welding is applied in the petrochemical sector to fabricate pipelines, pressure vessels, and other essential components. This is because the technique provides strong, corrosion-resistant welds suitable for harsh chemical environments.

TIG Welding vs. MIG Welding

Selecting between TIG and MIG (Metal Inert Gas) welding is crucial since each technique has distinct advantages and applications. Hence, understanding the differences enables welders to make informed decisions based on the specifications of their projects.

Precision

TIG welding often takes the lead when comparing TIG and MIG welding. This is usually because TIG welding provides thorough control over the heat input, resulting in precise welds. This precision allows the welding of thin materials and intricate designs. This makes TIG welding the preferred choice for projects that require accuracy and cleanliness.

Versatility with Materials

TIG welding is compatible with stainless steel, titanium, and super alloys, while MIG welding excels in applications with common materials like carbon steel and aluminum. Therefore, TIG vs MIG welding often sees TIG as the preferred method in industries requiring diverse material applications.

Spatter Formation

The TIG welding process does not result in the formation of spatter. Therefore, this promotes a clean work environment and reduces the need for extensive post-weld cleanup. In contrast, MIG welding might produce more spatter with its consumable wire. Thus, the spatter formed in MIG welding might need extra cleaning.

Speed and Efficiency

TIG welding is generally slower than MIG welding. MIG welding’s continuous wire feed makes it faster and more efficient. Consequently, MIG welding applies well in high-production projects, including automotive assembly lines.

Ease of Learning

TIG welding’s complexities require a higher skill level, making it less suitable for beginners. In contrast, MIG welding’s less complicated process utilizes a wire-fed system. Thus, this makes it easier for novices to understand.

Zintilon Expert Sheet Metal Fabrication Services

TIG welding finds widespread use in various industries. However, manufacturers must choose a suitable material before delving into TIG welding. This involves evaluating its diverse properties to ensure it meets the project requirements. After considering all factors, quality welding services become indispensable.

At Zintilon, we redefine precision in custom sheet metal fabrication. Our dedicated experts specialize in handling all your welding needs. We guarantee precision, quality, and affordability, regardless of the volume. Moreover, we excel in turning raw sheet metal into products tailored to your requirements. Reach out to us today to harness the precision of our welding services in custom sheet metal fabrication.

Conclusion

In this comprehensive guide, we examined the versatility of TIG welding in sheet metal fabrication. The controlled heat input of TIG welding results in a spatter-free process and offers precision in joining materials.

Welders typically select between TIG and MIG welding based on the project’s requirements, the materials, and the desired balance between precision and efficiency. TIG welding is often the preferred choice for intricate work or projects that demand the highest level of precision. Conversely, MIG welding is commonly used in high-speed production settings.

FAQs

How Strong is TIG Welding?

People often consider TIG welding the strongest type because it generates intense heat. The slow cooling process adds up to create high tensile strength and flexibility.

Is TIG Weld Stronger Than MIG Weld?

TIG welding typically produces stronger joins than MIG welding. This is because TIG welders generate a narrow, focused arc that allows for better metal penetration. Moreover, when applied correctly, TIG weld beads exhibit minimal holes and defects, contributing to the weld’s strength.

Does TIG Welding Need a Filler Material?

A filler rod is typically used as part of the process in TIG welding. Generally, thicker materials require a filler rod to provide heat and additional material for a stronger joint. Additionally, a joint fabricated without a filler material may be less sturdy than one made with a filler material.

Great, Together