Aluminum is a popular material choice for CNC machining applications due to its favorable physical qualities. It is strong, making it suitable for mechanical parts, and its oxidized outer layer resists corrosion caused by the elements. These advantages have made aluminum parts popular in various industries; however, they are especially popular in the aerospace, automotive, healthcare, and consumer electronics sectors.

This article outlines some of the primary benefits of aluminum CNC machining and why it is one of the most popular rapid prototyping and production processes.

Why Aluminum in CNC Machining

Aluminum CNC machining has several advantages over other metals. These advantages include:

Corrosion Resistance

Depending on the quality, aluminum has a strong corrosion resistance, which offers protection against chemical wear and oxidization. 6061 is one of the most corrosion-resistant grades, and it is used in various applications to guard against corrosive environments.

Recyclability

Aluminum is highly recyclable, making it ideal for firms looking to decrease their environmental impact or minimize material waste while saving money. Because of the potentially huge amounts of waste generated by these operations while cutting workpieces, CNC machining applications frequently use recyclable materials.

Strength-to-Weight Ratio

Aluminum is used in many parts because of its great physical features, such as its lightweight yet high-strength nature. Aluminum’s qualities make it excellent for the production of crucial parts in a variety of industries, including automotive and aerospace. Automotive shafts and aviation fittings are two examples of parts that rely on CNC-machined aluminum.

It’s crucial to understand that different grades of aluminum serve different purposes. A general-purpose grade, such as 6061, has a high strength-to-weight ratio that is compatible with a wide range of parts. Meanwhile, maritime and aeronautical applications may require stronger aluminum, in which case a grade like as 7075 may be used.

Electrical Conductivity

Because of aluminum’s excellent conductivity, CNC-machined aluminum pieces are frequently used in electrical components. While not nearly as conductive as copper, pure aluminum can conduct around 37.7 million Siemens per meter at ambient temperature. Certain alloys may have lower conductivity, but aluminum is generally more conductive than stainless steel and other metals.

Machinability

Engineers usually prefer aluminum to other metals due to its machinability. Because this metal is easy to form and chip, it can be correctly and efficiently cut using CNC machining equipment. This high level of machinability decreases the machining job’s timeframe, making the procedure considerably more economical. Furthermore, aluminum’s machinability reduces the possibility of component deformation when cutting the workpiece, resulting in greater precision, accuracy, and repeatability.

Popular Aluminum Alloys for CNC Machining

Here are some of the popular aluminum alloys available for CNC machining, including their pros and cons:

Alloy 1100

This is the finest form of aluminum commercially accessible, having a minimum purity of 99%. It is quite workable and pliable. This makes it an excellent alternative for difficult shaping tasks.

Pros

- Excellent corrosion resistance

- Good machinability and workability

- It is soft and ductile

Cons

- It is not used for high-strength or high-pressure applications

- It fails to respond to heat treatment

Alloy 3003

3003 aluminum is pure aluminum with a manganese additive to boost its strength. It is an aluminum alloy with nominally 1.2% Mn, 0.12% Cu, and 98.6% Al.

Pros

- Excellent workability

- Good machinability

- Good corrosion resistance

Cons

- It cant be treated by heat

- It does not provide considerable fracture toughness when used in applications that require strength.

Aluminum 2024

2024 aluminum is a versatile, inexpensive aluminum alloy weaker than others on this list. It offers good machinability and workability and is easy to finish. Its main alloying components are copper and magnesium, which increase its strength and hardness.

Pros

- High tenacity

- Machinable and formable

- Long-lasting with a high fatigue strength

Cons

- Only weldable via friction welding

- Reduced corrosion resistance

Aluminum 5052

This alloy has the maximum strength of the non-heat-treatable grades. It has a higher fatigue strength than most other aluminum grades. It is resistant to the marine environment and saltwater corrosion, and it is pretty workable.

Pros

- Excellent corrosion resistance

- Machinable and workable

- High fatigue strength

Cons

- Cold working is the only way to harden

- Tensile and shear strength are reduced

Aluminum 6063

Architectural alloy is another name for it. It possesses reasonable mechanical properties, excellent finishing features, and high corrosion resistance. Most commonly seen in interior and exterior architectural applications and trim. Aluminum 6063 is mostly utilized in extrusion applications.

Pros

- Heat treatable

- High corrosion resistance

- Good for complex geometries

Cons

- It is not easily machined

- Lower strength

Aluminum CNC Machining Processes

Aluminum can be machined using a variety of CNC machining technologies available today. The following are some of these processes:

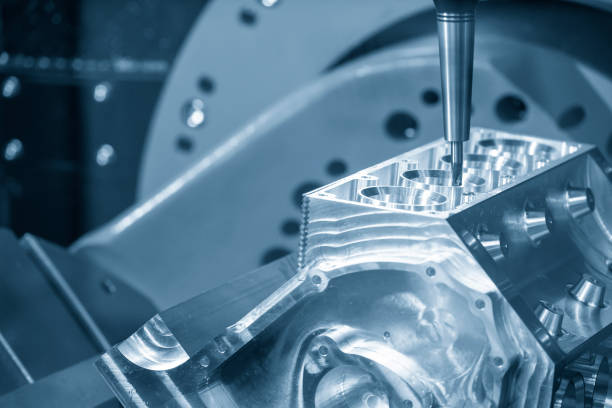

CNC Milling

CNC milling aluminum processes are the most widely employed in machining CNC aluminum parts. These processes include rotating a multi-point cutting along its axis while the workpiece remains stationary along its axis. The cutting tool, feed motion of either the workpiece, or both of them combined produces cutting action and, as a result, material removal. This motion can be performed along many axes.

CNC Turning

The workpiece rotates in custom CNC turning operations, but the single-point cutting tool remains stationary along its axis. Depending on either the workpiece, cutting tool or the machine moves against the other to remove material.

Facing

In machining, face turning or face milling is used to create a flat cross-sectional area on the surface of a workpiece.

Pocketing

Pocketing, also known as pocket milling, is a type of CNC aluminum milling machine in which a hollow pocket is machined in an object.

CNC Drilling

CNC Drilling is the process of creating a hole in a workpiece. A multi-point rotating cutting tool of a specific size goes in a straight line perpendicular to the drilled surface, effectively making a hole.

Steps To Improve Dimensional Stability In CNC Aluminum

These are the steps to follow to boost dimensional stability in CNC aluminum:

Improve the Workpiece Clamping Procedure

There are two methods for improving the clamping of aluminum workpieces. Clamping with a three-clawed self-centering chuck generates deformations in thin-walled cylindrical pieces. As a result, the end face compression approach comes in helpful in this situation. A cover plate compresses the end face, which is then tightened with a nut. This provides for good machining accuracy.

The second method works with thin-walled plate workpieces. Suction cups are used with the thin plate to ensure a uniform distribution of gripping force. Another technique is to employ a liquid medium to avoid clamping deformations.

Use the Right Method of Operation

Choose the appropriate feed speed, spindle speed, and cutting depth. Front and back symmetrical machining; Multi-layer aluminum machining of all workpiece cavities; drill first and then mill when machining hollow parts.

Reduce Internal Stresses In the Metal Piece

Dimensional instability is mainly determined by internal stresses, with no external forces involved. The most typical methods for removing internal stresses in aluminum alloys are vibration treatment and natural or artificial aging of the working piece. According to the ASM Handbook, three ways can be utilized to relieve stress.

The first involves controlled plastic deformation of the material under compressive or tensile pressure. This procedure is only relevant to open-die forgings. The second method comprises thermal treatments such as subzero or cold stabilization, in which the material is exposed to cyclic temperatures ranging from -73 to 100 degrees Celsius.

Common Problems In Aluminum Alloy Machining

There are some common problems to watch out for during CNC aluminum machining, and they include:

Surface Mouldy and Unmachined

Cutting fluid causes the majority of problems while CNC aluminum milling alloy. Due to the lack of cutting fluid product design, it is impossible to avoid issues during the machining process. Mildew is one of the expressions of non-machining of aluminum alloy. Aluminum alloy mildewing is typically caused by cutting fluids with insufficient aluminum corrosion inhibition and microbial control.

The mildewing phenomena induced by the two causes vary; however, in most situations, the mildewing is caused by insufficient aluminum corrosion inhibition ability to cut fluid. When mildew appears, it should begin by improving the corrosion prevention ability of the cutting fluid and the storage mode after machining.

Sticking knife, Rotten Teeth, and unqualified Machined Surface finish During Tapping

Because aluminum alloy has soft characteristics and a low melting point, it is possible to have issues like rotten teeth or a stuck knife in a poor processing environment. Cutting fluid with good lubrication and cooling performance should be utilized in addition to altering processing parameters, such as avoiding medium-speed, easy-to-stick knife processing.

Residue on the Machined Surface Affects the Later Cleaning

After machining, aluminum alloys typically require cleaning. If the cleaning ability of the aluminum alloy cutting fluid is poor, residue will form on the aluminum alloy machined surface, impairing the look or later code spraying treatment. It is frequently associated with the construction of an emulsification system and the cleaning of cutting fluid products.

Excess Foam

During machining, cutting fluid foam is typically avoided. Poor machining outcomes and low efficiency will result from inadequate cooling induced by foam and severe tool wear. The 5-axis machining center, in particular, has higher requirements for cutting fluid foam, and cutting fluid that lacks anti-foaming and defoaming ability will cause abnormal elevation of liquid level, triggering the liquid level alarm and causing the machine tool to stop working usually. The performance of cutting fluid foam can be improved by adding a defoamer and designing the system for cutting fluid products.

Overcoming Challenges in CNC Machining Aluminum

Despite the challenges faced during aluminum CNC machining, there are still some things to overcome these challenges. They include:

Deal With the Softness and Malleability of Aluminum

While the suppleness of aluminum makes it easier to manufacture, it is also prone to distortions, especially when clamped incorrectly. Maintain the part’s integrity by using adequate work-holding fixtures and avoiding undue force.

Reduce Tool Wear and Ensure Precision

Aluminum’s sticky nature can hasten tool wear, affecting long-run precision. To increase tool life and preserve precision, use carbide or diamond-tipped tools.

Avoiding Material Welding on the Cutting Tool

Aluminum is known for becoming “sticky” during machining. This stickiness can lead the material to fuse onto the tool, especially at high speeds. To avoid this, employ adequate tool coatings such as titanium carbonitride (TiCN) and appropriate coolants to dissipate heat and prevent material buildup.

Common Surface Finishes in Aluminum CNC

Here are some common surface finishes in aluminum CNC:

Mechanical Finishing

Mechanical finishes, as opposed to a single technique, involve various processes used to modify the surface of aluminum parts. Abrasive blasting, grinding, and polishing are common examples.

Instead of employing chemicals, mechanical force is used with abrasive media to smooth the surface of the aluminum. This can make it look better or prepare it for another finishing step.

Powder Coating

Many product designers would pick powder coating for vivid, long-lasting colors with good UV resistance. Aluminum parts are cleaned and readied before spraying with dried paint powder on the aluminum surface with an electrostatic gun. The powder-coated aluminum pieces are then baked to melt and cure the coating into a smooth finish.

Powder coatings are not as durable and hard as anodized aluminum, but they provide an excellent appearance and excellent corrosion protection as long as the coating is intact. Powder coating is also less harmful to the environment than liquid painting, which uses solvents, including volatile organic compounds (VOCs).

Anodizing

Anodizing is a process that is often used to improve the wear resistance and corrosion of aluminum products. It can also provide other desirable benefits, such as enhanced heat dissipation and color acceptance.

Unlike coatings and paints, anodizing does not apply an external product to the outside of the aluminum. An electrochemical method is instead utilized to induce the naturally occurring coating of aluminum oxide to thicken. This shields the underlying aluminum from its surroundings and allows it to take dyes. However, the color options for anodizing are fewer than those for powder coating.

PVDF Coating

PVDF coatings are resin-based coatings with incorporated color pigment particles. They should be applied to the aluminum product in manufacturing and can produce a wide range of matte-finish colors.

PVDF coatings are suitable for outdoor applications such as aluminum wall cladding because they are highly corrosion-resistant, fade-resistant, and chemically resistant. They are less expensive than powder coatings and can be placed in a thinner layer. Finally, while this aluminum coating is slightly more wasteful than powder coating, it contains no hazardous VOCs.

Applications of CNC Machining Aluminum

Aluminum alloys have several advantageous features. As a result, CNC-machined aluminum parts are indispensable in a variety of industries, including the following:

- Automotive

Similar to the aerospace industry, various parts in the automotive industry, such as shafts and other components, are constructed of aluminum.

- Aerospace

Several airplane fittings are built of aluminum CNC machine due to their high strength-to-weight ratio.

- Cryogenic

Aluminum parts are suitable for cryogenic applications because they preserve mechanical qualities at subzero temperatures.

- Electrical

CNC machined aluminum parts with strong electrical conductivities are frequently employed as electronic components in electrical equipment.

- Sports

Aluminum CNC service are aslo used in the sport industry. They are frequently used to manufacture sports equipment such as baseball bats and sports whistles.

- Food/Pharmaceutical

Aluminum parts are significant in the food and pharmaceutical industries because they do not react with most organic compounds.

Best Practices For Aluminum CNC Manufacturing Techniques

Because of its excellent machinability and strength-to-weight ratio, aluminum is a popular metal for CNC machining. This machinability results in shorter machining times, which lowers labour and machine time costs. It also makes machining aluminum to the finer tolerances necessary for precision items easier.

However, the high coefficient of thermal expansion of aluminum might jeopardise tolerances if the workpiece becomes too hot during milling, particularly for thin parts. To avoid any bad impacts, create toolpaths that do not dwell on one location for too long. This technology allows heat to drain, and the toolpaths may be examined and adjusted in the CAM software that generates the CNC machining program.

If the forces are too great, the softness of some aluminum alloys allows for deformation during machining. So, to generate the proper amount of force during machining, use the recommended feeds and speeds for your specific grade of aluminum (see this article for basic formulas). Another rule of thumb for preventing deformation is to keep the thickness of your part more than 0.020 inches in all locations.

Another impact of aluminum’s malleability is forming a material-built-up edge on the cutting tool. This obscures the tool’s sharp cutting surface, dulls it, and lowers its cutting ability. Your part’s surface finish suffers as a result of the built-up edge. Experiment with cutting tool material to prevent developing a built-up edge; use carbide inserts instead of HSS (high-speed steel).

Conclusion

As you can see, aluminum has numerous advantages in your next CNC machining job. Aluminum is helpful for many applications due to its excellent machinability and availability of several alloys and treatments. Zintilon provides precise CNC machining services for a wide range of typical aluminum alloys, and we can assist you in selecting the perfect one. Make an account, upload your component, and discover what we can do for you!

Great, Together