Selecting the suitable surface finish for your project, either powder coating or anodizing, can be challenging. Both of these finishes have their unique advantages and disadvantages. Therefore, it is essential to understand their respective properties to guide your decision-making process thoroughly.

In this guide, we will explore the distinguishing characteristics, strengths, and limitations of anodizing and powder coating in-depth, allowing you to make an informed and successful decision.

What Is Powder Coating?

Powder coating process

Powder coating is another finish used on a wide range of metal objects. This procedure creates a protective and decorative layer on the surface of the treated goods.

Unlike other coating applications (such as painting), powder coating is applied dry. Powder coating uses no solvents, making it an environmentally benign option to other finishing procedures.

After cleaning the part, a technician adds the powder using a spray pistol. This gun gives the powder a negative electrostatic charge, which attracts it to the grounded metal component. The powder remains connected to the object as it cures in an oven, resulting in a uniform, solid layer.

The final coating is durable and appealing. It can be used in thick layers and a wide range of colors and textures. To learn more about the procedure, read our article on powder coating.

Features

`Here are some key features of powder coating:

- Process

Powder coating involves applying a dry powder of resin and pigment to a surface using an electrostatic spray gun. The charged powder particles adhere to the grounded surface. After application, the coated object is cured in an oven at high temperatures (typically around 350°F to 400°F), which melts the powder and forms a hard, durable finish.

- Durability

The cured finish is resistant to scratches, chipping, fading, and corrosion. This makes powder-coated items ideal for outdoor and high-traffic applications.

- Variety of Finishes

Powder coating is available in various colors, textures, and gloss levels, allowing creative and customized designs. It can mimic other finishes, such as metallic or matte, enhancing aesthetic finish.

- Environmental Impact

Unlike traditional liquid coatings, powder coating contains little to no volatile organic compounds (VOCs), making it more environmentally friendly. Overspray can be recycled and reused, reducing waste.

- Application Versatility

Powder coating can be applied to various materials, including metals such as aluminum, steel, and even some plastics. Its versatility suits numerous industries, including automotive, furniture, and architecture.

- Application Versatility

Powder coating can be applied to various materials, including metals such as aluminum, steel, and even some plastics. Its versatility suits numerous industries, including automotive, furniture, and architecture.

- Thickness Control

The thickness of the powder coating can be controlled during application, allowing for a consistent and even finish. This can enhance durability and appearance, especially in high-wear environments.

Pros

Here are the pros of powder coating:

- Uv Resistant

Powder coating is an excellent choice for surfaces requiring UV resistance. Dry powder is applied to the surface and then heated at high temperatures. This forms a robust protective barrier that can tolerate UV rays and is highly durable and corrosion-resistant. Powder coating is particularly suitable for outdoor surfaces.

- Less Expensive

In general, powder coating is less expensive than anodizing since it involves less time, energy, and materials. Anodizing, on the other hand, necessitates specialized, expensive equipment, making powder coating a more cost-effective option for finishing aluminum projects.

- Less Noticeable

Powder coating is often used for its less noticeable finish. When applied as a dry substance and heat-cured, it produces a matte finish reflecting less light than anodized surfaces. Powder coating is available in various colors, allowing for finishes that fit their surroundings.

Cons

Here are the cons of powder coating:

- Chipping problems with powder coatings.

The powder coating does not blend with the surface. This procedure increases the likelihood of chipping. As a result, it may not be suitable for heavy-duty applications.

- Material is susceptible to sunlight.

It is sensitive to prolonged UV exposure. However, it is more durable than standard paint solutions.

- Brittleness

While powder-coated surfaces are generally durable, they can be more brittle than other finishes, making them susceptible to chipping or cracking under impact.

- Limited Color Matching

Achieving an exact color match can be challenging, especially when trying to match a specific shade or finish already present on a part or surface. Variations can occur due to different batches of powder.

- Thickness Limitations

Powder coating may not be suitable for intricate or detailed designs that require very thin or precise applications, as the thickness of the coating can obscure fine details.

What Is Anodizing?

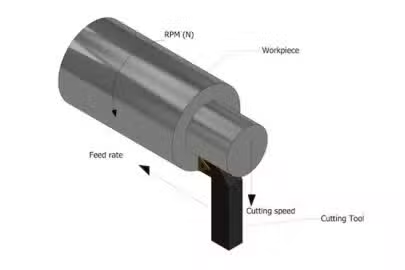

Anodizing process

Anodizing is a relatively simple electrochemical process. It includes immersing aluminum, alloys, or nonferrous metals in an electrolytic bath. It employs electrically charged liquid coatings via a cathode. So, it functions like paint on the metal surface.

Aluminum becomes the anode (anodic coating). It reacts with charged particles to produce aluminum oxide, which then mixes with the metallic surface. This signifies that the paint blends with the foundation material.

As a result, the coating is much less likely to chip than conventional paint. Most individuals favor this method due to its simple application. It also provides significant benefits. Some applications require this technique for long-term performance, and others will benefit from powder coating. For example, it can be used on fishing reels for sea and saltwater environments. This technique makes it salt-resistant, making the reels more durable and practical for fishing in this location.

Features

Here are the features of anodizing:

- Process

Anodizing involves immersing the metal in an electrolyte solution and passing an electric current through it. This process creates a thicker, more protective oxide layer on the metal’s surface.

- Durability

The anodized layer significantly increases corrosion and wear resistance, making anodized aluminum suitable for harsh environments, including marine and industrial applications.

- Surface Hardness

Anodizing increases the surface hardness of aluminum, making it more resistant to scratches and abrasion. The resulting finish is often harder than the underlying metal.

- Aesthetic Options

Anodized aluminum can be dyed in various colors, allowing for customization while maintaining the metallic look. The dye is absorbed into the porous anodized layer, producing a vibrant and long-lasting finish.

- Low Maintenance

Anodized surfaces are easy to clean and maintain. The protective oxide layer helps prevent dirt and contaminants from adhering, making routine cleaning more straightforward.

- Environmental Resistance

The anodized layer offers excellent resistance to UV radiation, preventing fading and degradation over time. This feature is particularly beneficial for outdoor applications.

- Non-Toxic and Eco-Friendly

The anodizing process does not produce harmful emissions or byproducts, making it an environmentally friendly option for metal finishing.

- Adhesion Properties

Anodized surfaces provide excellent adhesion for paints, adhesives, and other coatings, which is advantageous for applications requiring additional surface finishing.

Pros

Here are the pros of anodizing:

- Corrosion and Damage Resistance.

This procedure integrates paint and metal. It improves rust and corrosion resistance and slows down the deterioration process, which benefits the agriculture, fishing, and industrial sectors. Anodized coatings perform well. Nonetheless, debris chipping coatings present significant hazards. However, the process exhibits lower chemical resistance.

- Ensures Longevity

The coating procedure creates an impenetrable contact between metal and paint. You can choose various colors and keep them for an extended period. Additionally, anodized metals are more durable. Most will survive further savagery and remain intact.

- Total Coverage

Dipping the metal in the bath produces a uniform surface. Curves are unnecessary unless they are planned. Furthermore, there are no empty nooks and crannies. Every metallic surface has an even covering.

However, tooling markings or faults in the original product is obvious even after an anodized finish. If you choose color dyeing or any coating, you must perform an additional sealing process. This process could be hot, cold, or mixed.

- Reusable Process

The electrolyte bath can be used for a variety of coating applications. It’s a method of celebrating natural longevity. Furthermore, it protects against volatile organic chemicals, releasing no harmful waste into the atmosphere. In summary, it is safe for both employees and the environment.

Cons

Here are the cons of anodizing:

- More Costly

Spray painting is less expensive than anodizing. However, the bath and the finished result are pricey. Prices for composite, die-cast, and anodized reels vary. The first two are lower-cost processes. The high expense of the anodization process drives up the pricing of the finished products. Other reels cost less because they employ powder coatings.

- Low Choice of Colors

This technique allows you to use a variety of colors. However, the powder is more flexible. Check out this approach for creating a matching anodized color.

- Initial Marks are More Visible

This technique has a uniform consistency. However, marks on the original metal will remain apparent. The smooth surface is appealing from an aesthetic standpoint. This method adds a rich appearance to the anodized aluminum.

Is Powder Coating Better Than Anodizing?

Anodizing vs powder coating

When comparing powder coating and anodizing, the choice ultimately hinges on specific project requirements, materials, and desired outcomes. Powder coating is versatile and can be applied to various metals, including steel and aluminum, making it particularly effective on ferrous materials. In contrast, anodizing is primarily used for aluminum, enhancing its durability and corrosion resistance, but it is unsuitable for all metals. In terms of durability, powder coating offers a tough protective finish that is resistant to scratches, chipping, and fading, and it is ideal for outdoor and high-traffic applications. However, it can be brittle and may chip under impact.

Anodizing provides a robust oxide layer that increases corrosion and wear resistance, often making a surface harder than the original metal and highly durable in challenging environments. Aesthetic appeal is another essential consideration. Powder coating boasts a wide range of colors, textures, and finishes, allowing for creative designs, while anodizing can be dyed but generally has a more limited color palette. Environmental impact is also a factor, with powder coating being more environmentally friendly due to low or zero volatile organic compound (VOC) emissions, and its overspray can be recycled. Anodizing is an eco-friendly process that produces no harmful byproducts, making it a sustainable choice for aluminum products.

Cost considerations play a significant role in decision-making as well. Powder coating often has lower initial setup and application costs, particularly for large-scale projects, though its longevity and durability may affect long-term expenses. Anodizing can be more expensive due to the complexity of the process and custom color options, but its durability can lead to lower maintenance costs over time. The application processes differ, with powder coating requiring electrostatic application followed by curing, which may only be suitable for some materials. At the same time, anodizing involves an electrochemical process that demands specific equipment and expertise.

Contrast Table

Below is a table comparing the features of powder coating vs anodizing process:

| Features | Powder Coating | Anodizing |

| Material Compatibility | Applicable to various metals and some plastics | Primarily for aluminum |

| Durability | Resistant to scratches, chipping, and fading | Highly durable with increased corrosion and wear resistance |

| Aesthetic Options | Wide range of colors, textures, and finishes | Limited color palette. It retains metallic look of aluminum and can be dyed |

| Environmental Impact | Low or zero VOC emissions; overspray can be recycled | Eco-friendly process with no harmful byproducts |

| Cost Considerations | Generally lower initial costs. It may have higher long-term maintenance costs | Higher initial costs. It potential for lower maintenance costs over time |

| Surface Hardness | Moderate hardness; less resistant to abrasion than anodized surfaces | Significantly increases surface hardness; more resistant to wear |

Conclusion

Powder coating and anodizing offer unique advantages and are suited to different applications and materials. Powder coating is known for its versatility, wide range of aesthetic options, and lower initial costs. It is an excellent choice for projects requiring creative finishes and durability in various environments. However, its brittleness and the need for precise surface preparation can be drawbacks in specific scenarios. On the other hand, anodizing enhances aluminum’s corrosion resistance and hardness, providing a long-lasting and low-maintenance finish that is particularly effective in harsh conditions. While it usually comes with higher initial costs and a more limited color palette, its eco-friendly process and superior surface properties justify the investment for many applications. Ultimately, the decision between powder coating and anodizing should be guided by specific project requirements, including the type of material, desired finish, environmental considerations, and budget constraints. Zintilon offers amazing surfcae finishing services that will suit all of your need. Contact us today to get started!

Great, Together