What is the chromate conversion?

Chromate conversion, also known chemically as acid aluminum chloride (AlCl3), is an important chemical intermediate that is widely used in organic synthesis and industrial production. Traditional preparation methods involve the use of chlorine and hydrogen, which are not only dangerous but also have a negative impact on the environment. The chromate conversion is a more environmentally friendly and efficient alternative, using safer raw materials to prepare chromate conversion.Advantages of the chromate conversion

Environmental Friendly

Compared with the traditional gas method for preparing chromate conversion, the chromate conversion uses more environmentally friendly raw materials and methods, which reduces harmful gas emissions and helps protect the environment.Resource Sustainability

While traditional methods rely on limited resources such as chlorine, the chromate conversion uses more sustainable raw materials such as aluminum powder and ammonium chloride, which is conducive to the sustainable use of resources.Application of Chromate Conversion in the Manufacturing of Machined Products

Electronic Component Manufacturing

Electronic components often require high-purity chemicals, and the chromate conversion provides highly pure materials used in circuit board manufacturing and the semiconductor industry.Material Synthesis

Parts in machined products often require specific materials. The chromate conversion can be used to synthesize materials with special properties to meet the needs of different industrial sectors.Environmentally Friendly Coating

In the face of increasingly stringent environmental regulations, environmentally friendly coatings prepared by the chromate conversion are favored. These coatings contain no harmful substances and help reduce environmental pollution.Metal Surface Treatment

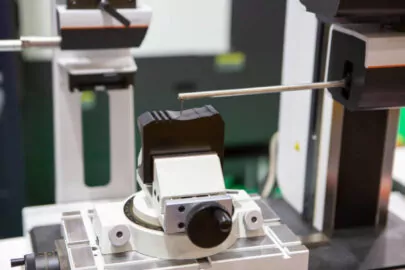

Surface treatment of metal parts is critical in machined product manufacturing. The chromate conversion can be used for oxidation, corrosion protection and modification of metal surfaces, improving the durability and performance of parts. At present, our company generally applies this technique to environmentally friendly coatings and metal surface treatments.Application of Chromate Conversion in Surface Treatment

Chromate conversion is a chemically stable acidic substance. In surface treatment, chromate conversion can passivate the metal surface, increase surface hardness, improve coating adhesion, and play a role in improving metal corrosion resistance. At the same time, it can also play a role in beautification and decoration.The Principle of Chromate Conversion in Surface Treatment

So what is the process of chromate conversion surface treatment? Chromate conversion treatment is a complex multi-phase reaction carried out at the metal solution interface. The formation process of the chromate conversion film can be roughly divided into the following three steps after analysis and sorting: Firstly, the metal surface is oxidized and transferred into the solution in the form of ions, producing atomic hydrogen. Secondly, the nascent atomic hydrogen promotes the reduction of a certain amount of hexavalent chromium into trivalent chromium, and due to the increase in pH value at the metal solution interface, the trivalent chromium precipitates in the form of colloidal chromium hydroxide. Then the chromium hydroxide colloid adsorbs and combines a certain amount of hexavalent chromium from the solution to form a chromate conversion film with a certain composition at the metal interface. When the film is slightly damaged, soluble hexavalent chromium compounds can passivate the area again to prevent corrosion.Specific Applications of Chromate Conversion Surface Treatment

Chromate conversion surface treatment is not suitable for all metal materials. Most of the time it is only used for metal materials such as aluminum, aluminum alloys, zinc, copper, steel, iron, tin, and cadmium. Specific application scenarios include:Anti-rust Treatment

The chromate conversion film has strong binding force with the matrix, has a relatively tight structure, and has good chemical stability. Coating a layer of chromate conversion solution on the metal surface can prevent the surface of the metal material from rusting and protect the metal surface from external contaminants.Cleaning Process

Chromate conversion solution can effectively remove dirt and grease from metal surfaces, making them cleaner.Increase Surface Hardness

After metal materials are treated with chromate conversion, a dense passivation layer can be formed, thereby improving the hardness and wear resistance of metal materials. At the same time, the color and appearance of the passivation layer are improved.Improve Coating Adhesion

Chromate conversion treated metal surfaces can greatly improve coating adhesion and durability.Shading

Chromate conversion can be used as a coloring treatment for metal materials to improve the gloss and color of their surfaces and make them more decorative. The treated metal outer layer has rich color, ranging from colorless, transparent or milky white to yellow, golden yellow, light green, green, olive, dark green and brown, and even black.Precautions for Chromate Conversion Surface Treatment

Chromate conversion is highly corrosive, so it is necessary to strictly abide by relevant safety operating procedures and maintain good ventilation and protective measures during operation. The treated metal surface needs to be maintained during use to avoid mechanical scratches and chemical corrosion. Chromate conversion surface treatment is suitable for large-area and irregular-shaped metal objects. For the treatment of small parts, other more suitable surface treatment methods are used. The surface treatment of metals with different substrates requires different proportions of chromate conversion solutions, and the colors and compositions obtained after treatment will also be different.ZINTILON’s Chromate Conversion Surface Treatment Services for Metal Parts

Chromate conversion surface treatment helps improve the corrosion resistance and adhesion of metal surfaces, and its cost is relatively low, so it is widely used in various industries. Our company is able to provide chromate conversion surface treatment for a variety of metal parts. From parts manufacturing to surface finishes of parts, we can provide you with high-efficiency, high-quality services. If you have ideas about parts manufacturing or part surface treatment, then we will be your best choice. To find out more about our services or to get a quote, please do not hesitate to contact us.Read More

- Chromate Conversion in Machined Products: Innovative and Efficient Synthesis Methods – Zintilon

- Automotive Car Chassis: Structure, Types, And Design Trends – Zintilon

- Understanding CNC Machining: A Guide to Common CNC Machine Types and Their Uses – Zintilon

- What Is 5 Axis CNC Machining? Everything You Need to Know – Zintilon

- Anodized Aluminum Colors: What Are the Available Options? – Zintilon

Great, Together