Innovation is the driving force in the current manufacturing landscape. Many industries now require precision, high-quality products, and fast turnaround times. That is where rapid prototypes come into play.

Rapid prototypes are early-stage models that serve as the foundation of product development. These prototypes provide invaluable insights to manufacturers on the design and manufacturability of the products. They are cost-effective options to help minimize risks and accelerate product to market.

This article will take you through the various types of prototypes and how you can benefit from them. You will also learn the best practices for prototyping to help you stay ahead in the ever-evolving landscape of modern manufacturing.

What Are Rapid Prototypes?

Rapid prototypes are more like ideas brought to life. They are produced using a set of techniques for quickly producing a physical part or assembly from three-dimensional computer-aided design (CAD) data.

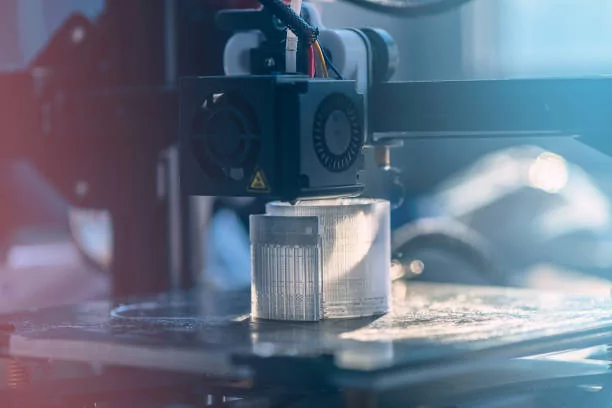

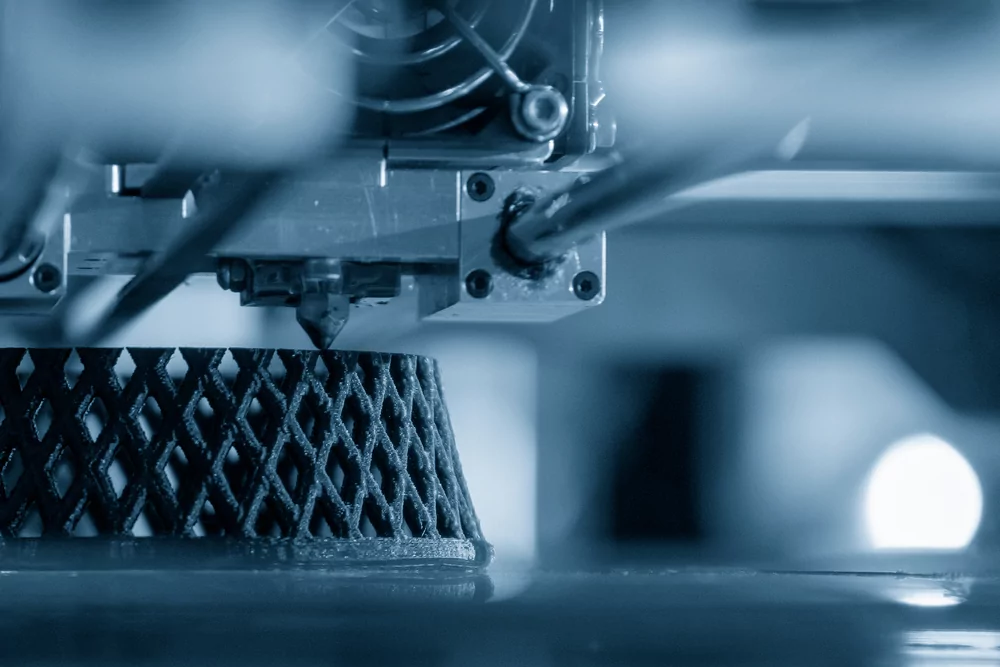

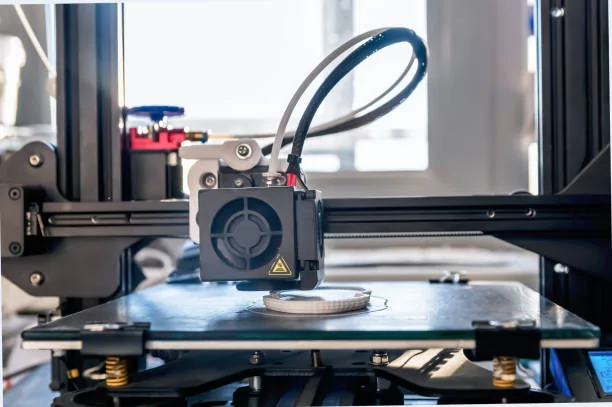

3D printing (additive layer manufacturing) technology is frequently used to create the part or assembly. The method of creating 3D objects by adding a layer-upon-layer material is called additive layer manufacturing, also known as 3D printing.

Unlike traditional subtractive methods such as CNC machining, additive layer manufacturing does not require tooling. When most people think of rapid prototyping, they only think of rapid prototyping 3D printing technology. However, rapid prototypes are also produced with CNC machining, injection molding, and other machining processes.

Rapid prototyping can be used at any stage of the production process, from concept development to final testing. Effective rapid prototype production shortens the product development cycle and allows designers and engineers to evaluate and modify their ideas faster and more effectively. Rapid prototypes allow for quick modification and refinement of designs, which can aid in identifying and resolving problems early in the development process. Rapid prototypes can reduce costs, reduce the risk of errors, and shorten the time to market for new products.

Types of Rapid Prototypes

Now that we’ve got a hang of what rapid prototypes are, let’s dig into the different types they come in. It’s not a one-size-fits-all situation; several types are tailored to various needs. Here’s a rundown:

Proof of Concept

A proof of concept model is often the first prototype from the development process. These prototypes are used to confirm the viability of a project. They frequently have a crude appearance and design. A proof of concept’s primary objective is to test the idea underlying general assumptions and confirm that it can be implemented technically. This can be viewed as an examination of your design.

Visual Prototype

This is a prototype that shows what the finished product will look like. The visual/appearance prototype better illustrates the final product’s size, shape, color, and texture. Such a visual-touch component adopts the appearance and texture of the actual product. A visual prototype resembles a realistic 3D rendering if a concept prototype is like an imprecise 3D sketch. The latter, which combines style and utility, frequently helps with product demonstration. It also displays the viability of the product before entering the market.

Working Prototype

A working prototype is a model or early example of a product created to test an idea or procedure to improve or show it to marketing firms and investors. It makes it possible to test the product’s usability and functionality, and it can assist in locating and resolving any potential design flaws. However, a functional prototype is sometimes a reliable indicator of a product’s viability in the marketplace.

Pre-production Prototype

Usually, this is the last test run before starting full-scale production. Pre-production prototypes and production samples can both assist you in identifying manufacturing problems and reducing potential risks. You can easily compare prices using this final prototype. The retailers and distributors who you are offering your new gadget want to see the real thing. A factory sample on hand eases your mind and facilitates your launch planning.

Why Are Rapid Prototypes Important?

Rapid prototypes are essential for various reasons including low volume production. Here are some of the most common importance of raid prototypes in the manufacturing world:

Speed

Rapid prototypes are like the express lanes of product development. Traditional methods often involve a slow and sequential process where you have to wait for one phase to finish before moving on to the next. With rapid prototypes, you’re on the fast track. They allow for quick iterations and adjustments, drastically reducing the time it takes to move from conceptualization to a tangible model. This speed is crucial in today’s competitive market, where getting to market faster can make all the difference.

Test a Full Range of Designs

Think of rapid prototypes as your design playground. You’re not stuck with one idea; you can play with as many variations as you want. This is a game-changer because it allows you to explore the creative landscape without the fear of commitment. By testing different designs, you can discover unexpected solutions, identify potential issues early on, and ultimately refine your rapid prototyping model to meet your vision and your users’ needs. It’s the ultimate freedom to innovate without constraints.

Part Consolidation

Complexity can be the enemy of efficiency. Rapid prototypes give you the chance to see if you can simplify things. By physically assembling and testing parts, you can identify opportunities for consolidation. This doesn’t just save time during production; it can lead to cost savings and a more streamlined final product. It’s like finding that sweet spot where every part plays a crucial role without unnecessary complexity, making your product not just functional but elegant in its simplicity.

Test Materials

Rapid prototypes are invaluable tools for material testing in the early stages of product development. Different materials can be incorporated during the prototype phase to assess their viability and performance. This proactive approach ensures the identification of optimal materials, ensuring that the final product meets the required durability, functionality, and aesthetics standards. By enabling material testing within the prototype stage, development teams can make informed decisions, mitigating the risk of selecting suboptimal materials that could compromise the quality of the end product.

Risk Mitigation

The role of rapid prototypes in risk mitigation extends beyond early issue identification. Prototypes serve as tangible representations that allow stakeholders to foresee potential challenges and mitigate risks more comprehensively. By physically interacting with a prototype, stakeholders can evaluate the design, functionality, manufacturability, and usability aspects. This comprehensive assessment facilitates the identification and resolution of issues before they escalate, providing a robust risk mitigation framework throughout the development process.

Challenges in Rapid Prototyping

Even though there are several benefits of rapid prototypes, some challenges can be faced when producing it. However, manufacturers must prioritize selecting prototyping methods and materials that collectively contribute to CNC rapid prototype production’s accuracy, quality, and efficiency.

Complexity of Design

The complexity of design presents a significant challenge in rapid prototyping. While this technology is adept at transforming ideas into tangible models, intricate designs can strain the capabilities of specific prototyping methods. Accurately reproducing complex geometries and fine details requires carefully considering the prototyping techniques and materials used. Overcoming this challenge involves selecting ways to faithfully represent the design’s intricacies, ensuring that the prototype adequately reflects the final product’s intended form and function.

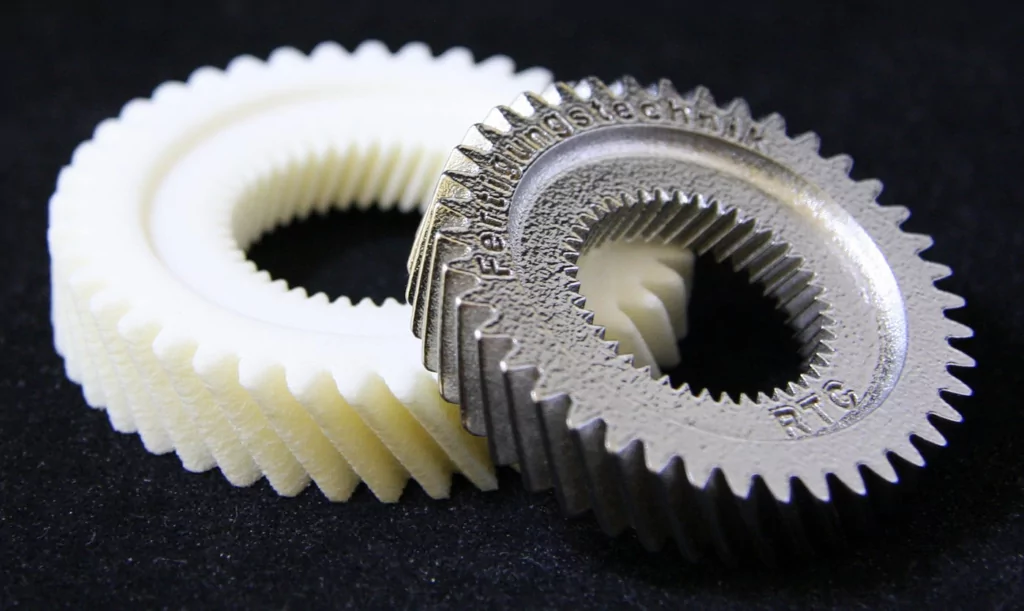

Cost and Availability of Materials

The cost and availability of materials constitute substantial challenges in rapid prototyping. Some materials necessary for accurately simulating the properties of the envisioned product may be expensive or difficult to procure. Striking a balance between cost-effectiveness and needing materials that closely mimic the intended product characteristics is delicate. Additionally, the availability of diverse materials suitable for different prototyping methods plays a crucial role in determining the overall accessibility and affordability of the rapid prototyping process.

Lack of Skills and Well-Trained Staff

Implementing rapid prototyping technologies effectively requires a specific skill set, and the need for well-trained staff proficient in these technologies poses a significant challenge. Without adequately skilled personnel, there is a risk of underutilizing rapid prototyping resources, leading to inefficiencies, errors, and extended project timelines. Addressing this challenge involves investing in training programs and educational initiatives to enhance the workforce’s expertise. Bridging the gap in skills ensures that the benefits of rapid prototyping are maximized and that projects are executed with precision and efficiency.

Accuracy and Quality of Prototype

Ensuring the accuracy and quality of prototypes is a paramount challenge in rapid prototyping. While these prototypes aim to represent the final product, achieving high accuracy in dimensions, surface finishes, and material properties can be challenging. Variations between the prototype and the intended design can occur, leading to discrepancies in product performance evaluation. Addressing this challenge requires a meticulous selection of prototyping methods and materials that align with the desired precision and quality standards, ensuring that the prototype effectively mirrors the intended end product.

Software Capabilities

The software’s capabilities in rapid prototyping significantly impact the efficiency and effectiveness of the process. The challenge lies in selecting software that seamlessly integrates with the chosen prototyping method and provides the necessary design optimization and simulation tools. Incompatibility or limitations in software capabilities can hinder the translation of design concepts into accurate prototypes. Overcoming this challenge involves investing in cutting-edge software that supports the intricacies of the design and manufacturing processes, ultimately enhancing the overall precision and quality of the rapid prototyping outcomes.

Applications of Rapid Prototypes

There are various applications of rapid prototypes, and several industries use them. Rapid prototypes contribute to innovation and enhanced product development processes in the medical, automotive, and aerospace sectors by facilitating efficient design iteration, validation, and testing.

Medical Industry

Rapid prototyping has revolutionized the medical field, offering a myriad of applications. Prototypes play a crucial role in the medical industry in developing customized implants, prosthetics, and medical devices. Surgeons can utilize accurate 3D-printed models of patient-specific anatomies for pre-surgical planning, leading to increased precision in complex procedures. Additionally, rapid prototypes facilitate the creation of medical instruments and equipment prototypes, enabling efficient testing and refinement before mass production.

Automotive Industry

The automotive industry has embraced rapid prototyping to streamline the product development. Prototypes are employed to design and test various automotive components, from intricate engine parts to exterior body panels. This accelerates the design iteration cycle and allows for rapid validation of concepts, reducing time-to-market. Functional prototypes also aid in evaluating safety features, vehicle aerodynamics, and overall performance. CNC rapid prototyping enhances vehicle design innovation and contributes to the manufacture of high-quality, reliable automotive products.

Aerospace Industry

Rapid prototyping is a vital tool for designing and testing complex components in the aerospace sector. Prototypes are utilized to create models of intricate aerospace structures, ensuring that designs adhere to stringent safety and performance standards. The aerospace industry leverages rapid prototyping to develop lightweight yet durable components, leading to aircraft design and technology advancements. This iterative approach enables engineers to refine techniques, assess structural integrity, and optimize performance, ultimately contributing to advancing aerospace systems.

Zintilon Outstanding Rapid Prototyping Services

We at Zintilon recognize the value of efficient prototyping in creating prototypes. We offer superior rapid prototyping services through cutting-edge manufacturing techniques like 3D printing, CNC machining, and sheet metal fabrication. At Zintilon, we deliver exceptional services covering the entire spectrum of manufacturing, from initial prototyping to full-scale production.

Our team of skilled professionals and advanced machinery like Hermle 5 axis CNC machine center guarantee that every detail of your prototype is meticulously crafted, meeting the highest quality standards. We tailor our rapid prototyping services to suit the unique needs of your project, ensuring a customized and optimized experience.

Our commitment to excellence ensures top-tier quality, significantly lowers production costs, and reduces time-to-market for your projects. Our cutting-edge rapid prototyping services are designed to bring efficiency, precision, and innovation to your product development journey. Get a quote today for your prototyping and production needs.

Conclusion

Rapid prototypes speed up production across diverse industries, from medicine to aerospace and automotive. Despite challenges, these prototypes offer a dynamic pathway to transform ideas into tangible solutions swiftly. As technology evolves, the ongoing embrace of rapid prototyping promises to drive efficiency, spur innovation, and bring outstanding products to the forefront of global industries.

However, you must work with a reliable manufacturing partner to ensure unmatched speed and efficiency with rapid prototyping. Zintilon‘s rapid prototyping services is your gateway for groundbreaking products. Contact us today!

Great, Together