CNC Milling Service

- 3/4/3+2/5 CNC milling machines

- World-class machines such as Hermle

- Lead time as fast as 3 day

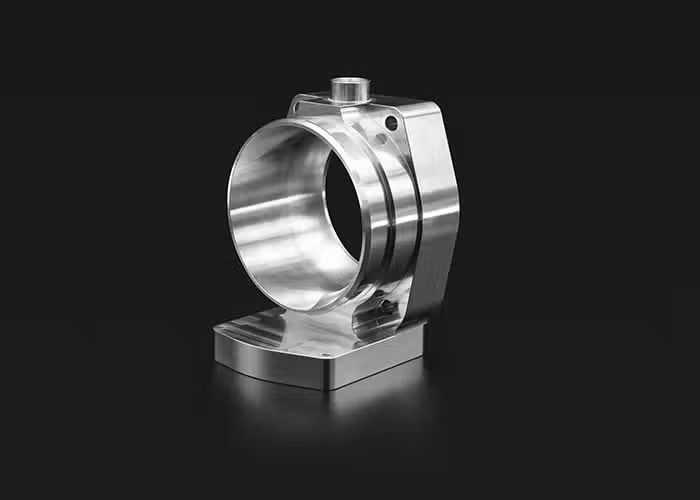

Reliable CNC Milling Service

CNC Milling Materials

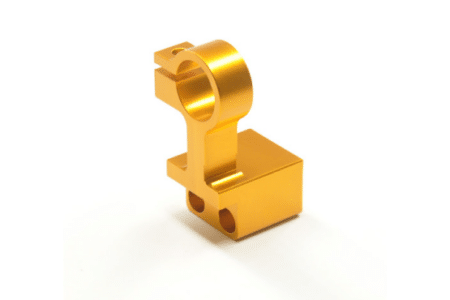

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

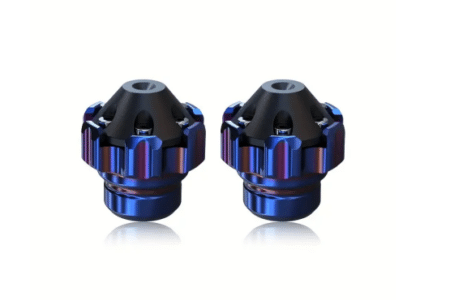

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Surface Finishing for CNC Milling

Why Custom CNC Milling Service at Zintilon

1-to-1 Quote Analysis

Just upload your 2D drawings or 3D models and you will get quote feedback in 24 hours. Our specialized engineers will analyze your design to avoid misunderstanding, communicate with you and offer an affordable price.

High Quality Production Parts

The responsible and rigorous attitude towards materials, milling operations, surface finishing and CMM inspection guarantee the consistent quality from prototyping to production parts. We won’t bother to check the parts quality before delivery.

Fast Lead Time

The introduce of advanced 5 axis CNC machining centers and professional quoters ensure the fast lead time. We set the priority for the arrangement of the order according to the requirements and order complexity.

Instant Communication

For the sake of your benefits, every customer will have technical support to get in touch with us from quotation to delivery. You will get fast feedback for any question until it’s confirmed that you receive the satisfied parts.

CNC Milling Tolerances and Standards

Type

Tolerance

Applications of CNC Milling Services

CNC Milling FAQs

to CNC Milling

Precision CNC Milling

Prototyping

- Advanced Technology: CNC, CMM inspection, elite engineers etc.

- Quick Response: Full support to ensure problem solved.

- Customized service: Customize precision machining solutions

Production

- Reasonable planning: precision resource allocation to ensure quick cycle time.

- Machining SOP : advanced technology and strict QC processes.

- Flexible Production: from rapid prototyping (1-20pcs) to low-volume production (20-1000pcs).