ZTL TECH is now Zintilon. We’ve updated our name and logo for a fresh start. Check Now

Bead Blasting

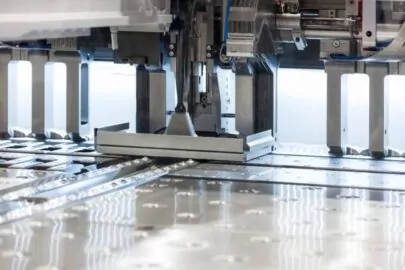

Bead blasting is a cold working surface finishing technology that uses high-speed shot and iron shot to impact the parts surface to improve some of the mechanical properties of the parts and change the surface state.

Bead blasting is mainly used to improve the fatigue strength and stress corrosion resistance of metal parts.

Applicable Materials

Aluminum

Texture

Smooth, matte

Colors

Clear

Purpose

Improve the mechanical strength, wear resistance, fatigue resistance and corrosion resistance of parts, clean surface and optimizie residual stress

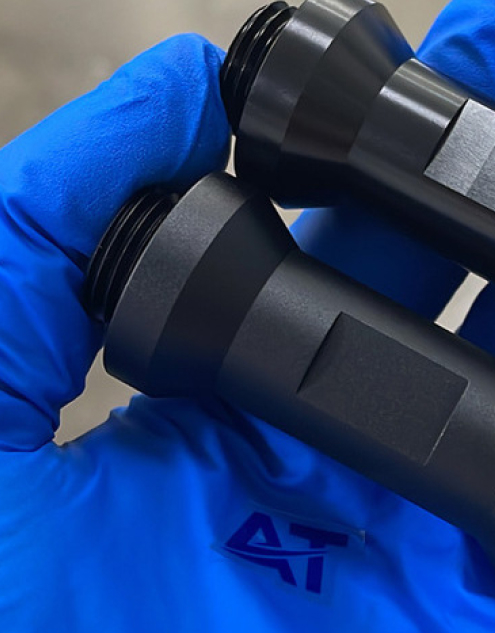

Materials for Bead Blasting

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Price

$ $ $

Lead Time

< 7 days

Tolerances

±0.001mm

Max part size

NA

Min part size

NA

Design Considerations

- Correct pressure is critical due to the difference in hardness and wear resistance of the material. Lower pressures (around 50 PSI) are suitable for softer materials and delicate surfaces, while higher pressures are better for harder surfaces.

- Choose the appropriate peening media based on the desired finish. Finer beads can create a smooth satin finish, while coarser beads provide a rougher texture.

- For threads or reaming holes, plugging is required if tolerances are very tight because of thickness variations.

- Avoid peening thin walls, as they tend to deform easily.

- Parts with complex geometries can be difficult to finish uniformly.