Anodizing

Anodizing helps with corrosion resistance, increases surface hardness, and improves wear resistance, serving both functional and aesthetic purposes.

There are mainly 3 types of anodizing mainly based on the type of electrolyte and the properties of the generated oxide film: chromic Acid Anodizing (Type I Anodizing), sulfuric acid anodizing (Type II Anodizing) , hard anodizing (Type III Anodizing). Anodizing can also be divided into 2 types according to film thickness: general anodizing and hard anodizing.

Zintilon offers both general anodizing and hard anodizing service.

Materials for

Anodizing

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

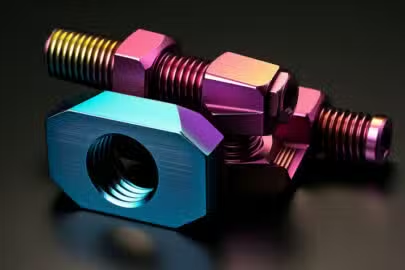

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Design Considerations

- Anodizing has insulative properties, so anodized parts have poor electrical conductivity.

- All edges and corners on the components should be rounded with a radius of no less than 0.5 mm, and no burrs are allowed. This prevents local overheating and burning of the parts caused by the current concentration.

- Parts with rough surfaces can become smoother after hard anodizing. However, components already possessing an extremely smooth finish will lose some smoothness.

- The part must bear high voltage and current during hard anodizing. Special fixtures must, therefore, be designed to keep the part in good conductive contact. It will otherwise break down or burn the contact parts of the parts.

Color Options for Aluminum Anodizing

Black (Black MLW)

Clear

Red (Red ML)

Blue (Blue 2LW)

Orange (Orange RL)

Gold (Gold 4N)

Black

Natural

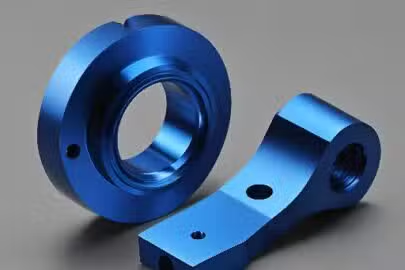

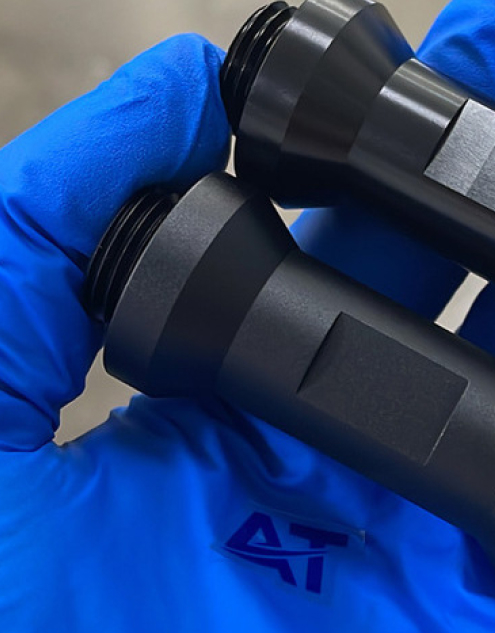

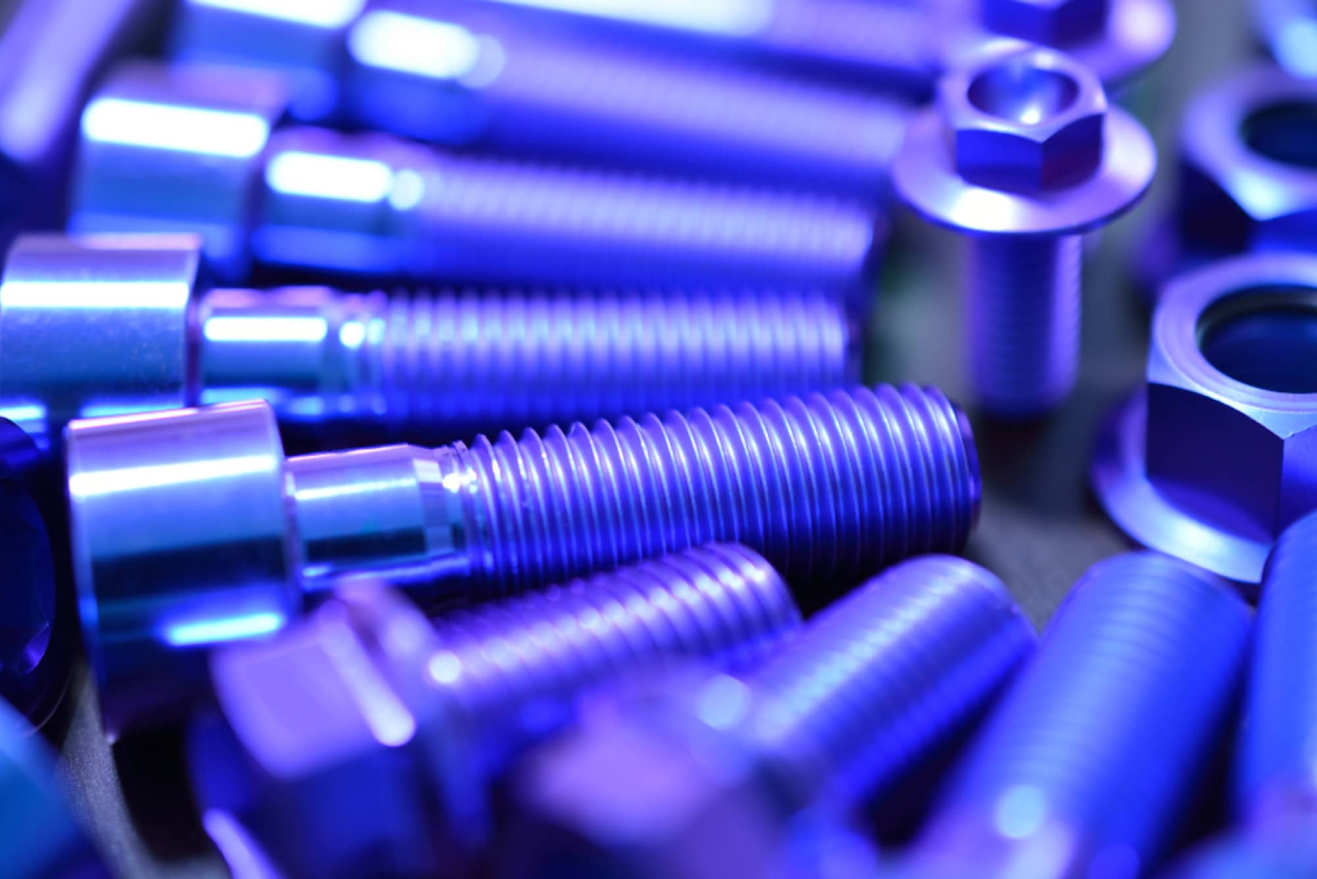

Gallery of

Anodized parts

Example of Anodized Part