Alodine

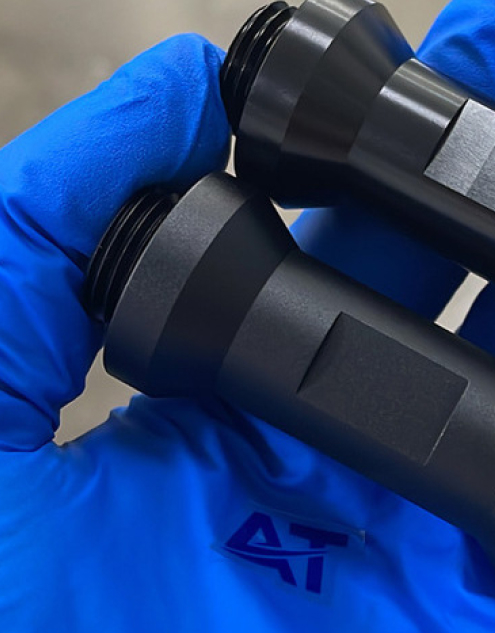

This is a trade name originally developed by Henkel to describe a specific chromate conversion coating surface treatment technology. In general, Alodine is a brand name for chromate conversion coating surface finishing technology

Alodine coatings can be colorless or colored, and can have different formulations depending on the application requirements.

Alodine surface finishing is commonly used for aluminum and aluminum alloys, forming a uniform, dense chemical conversion film of tens to hundreds of nanometers on the metal surface. This film improves corrosion resistance and can effectively isolate the metal from external corrosive media (such as water, oxygen, corrosive gases, etc.). Improve adhesion, hardness and wear resistance, provide good electrical insulation

Available Materials

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Design Considerations

- Choosing the right coating class: Alodine coatings come in different classes, such as Class 1A and Class 3. Class 1A coatings are thicker and provide excellent corrosion resistance, but will slightly reduce conductivity; Class 3 coatings are thinner and have minimal impact on conductivity, suitable for electrical components.

- Effect of coating thickness: Coating thickness is typically between 0.00001 and 0.00004 inches (0.25 to 1 micron). Although thin, it is enough to provide good protection. The choice of coating thickness should be determined based on the specific application needs.

- pH and temperature: Make sure the pH and application temperature of the Alodine solution are correct. The wrong pH or temperature may cause poor coating adhesion or defects such as spotting and sagging.

- Toxicity issues: Some Alodine solutions, such as those containing hexavalent chromium, can be toxic to the skin and require careful handling and proper disposal. Choosing a hexavalent chromium-free Type 2 coating can reduce this risk.