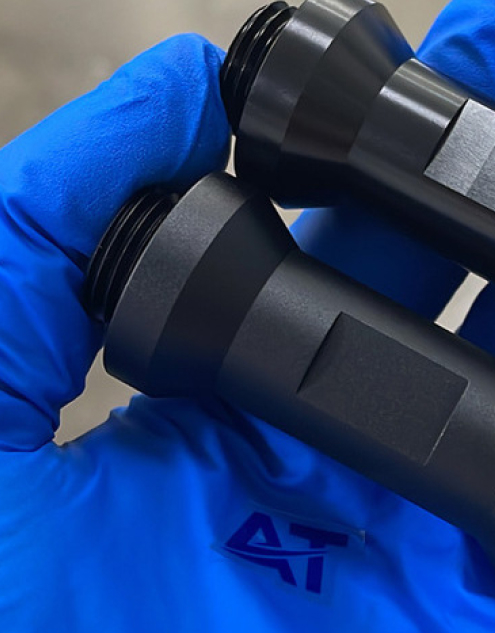

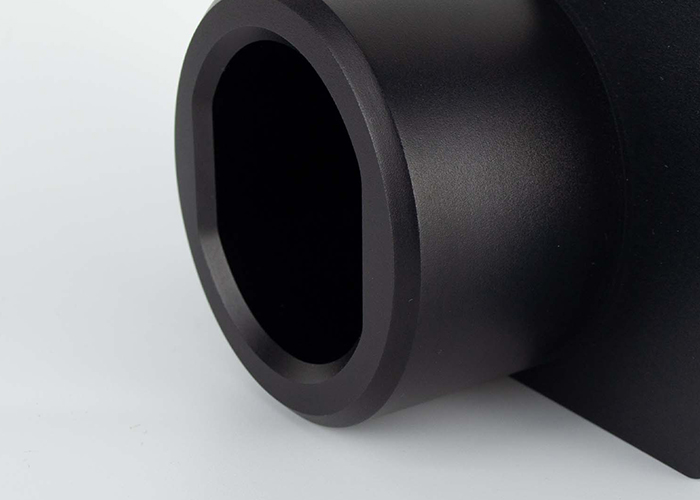

Black Oxide

Black oxide is a chemical conversion coating treatment that is primarily used on ferrous metals, but can also be adapted to materials such as stainless steel, copper, aluminum and zinc.

Black oxide changes the metal surface through a chemical reaction to create a surface layer that has good appearance, enhanced corrosion resistance and non-reflective properties.

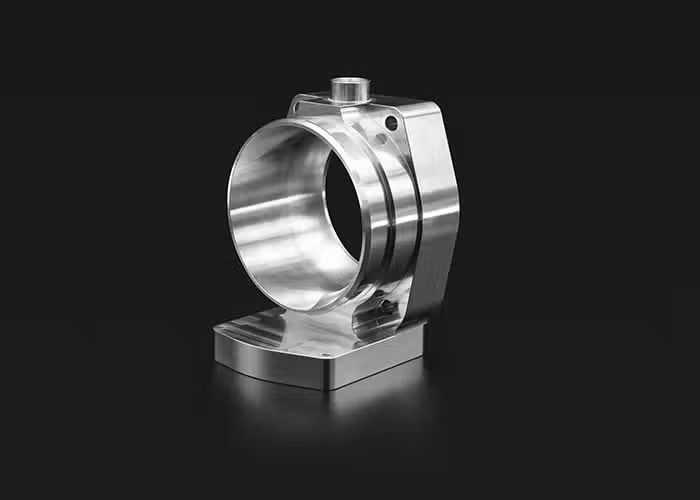

Available Materials

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Steel is a strong, versatile, and durable alloy of iron and carbon. Its applications range from construction materials and structural components to automotive and aerospace components.

Steel is strong and durable High tensile strength Corrosion resistance Heat and fire resistance Easily molded and formed.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Due to the low mechanical strength of pure magnesium, magnesium alloys are mainly used. Magnesium alloy has low density but high strength and good rigidity. Good toughness and strong shock absorption. Low heat capacity, fast solidification speed, and good die-casting performance.

Design Considerations

- The material has a significant impact on the acceptance of the black oxide coating. Black oxide is commonly applied to metals such as steel, stainless steel, and iron. Certain metals, such as some aluminum alloys, may require additional treatments because they do not bond as efficiently to black oxide coatings.

- The geometry of the part can affect the application of the coating. Complex shapes or hard-to-reach parts may require special considerations, such as the use of masking or selective coating techniques. Parts with deep grooves or intricate features may require careful planning to ensure an even coating.

- The thickness of the black oxide layer depends on the part application. Although black oxide coatings are typically thin, ranging from 0.0002 to 0.0005 inches, thicker coatings may be applied to parts that require added corrosion or wear protection. Coatings that are too thick may affect the size and function of the part, so the coating process must be precisely controlled.