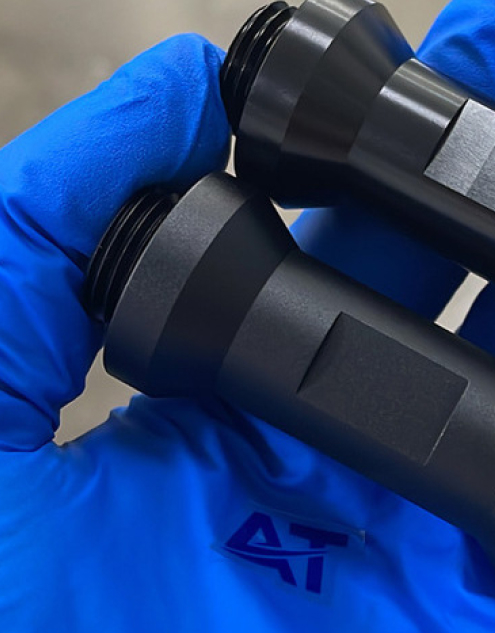

E-coating

E-coating is a surface finishing that uses electric current to deposit paint onto a conductive substrate. During electrophoretic coating, the part is immersed in a water-based coating tank containing charged paint particles. By applying direct current, the paint particles are attracted to the surface of the part and deposited evenly to form a coating.

According to the charge polarity of the paint particles, electrophoretic coating is divided into anodic electrophoresis (AED) and cathodic electrophoresis (CED).

Available Materials for E-coating

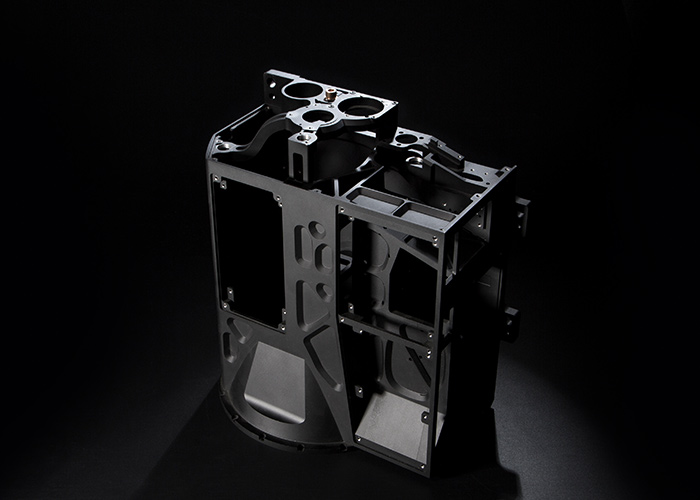

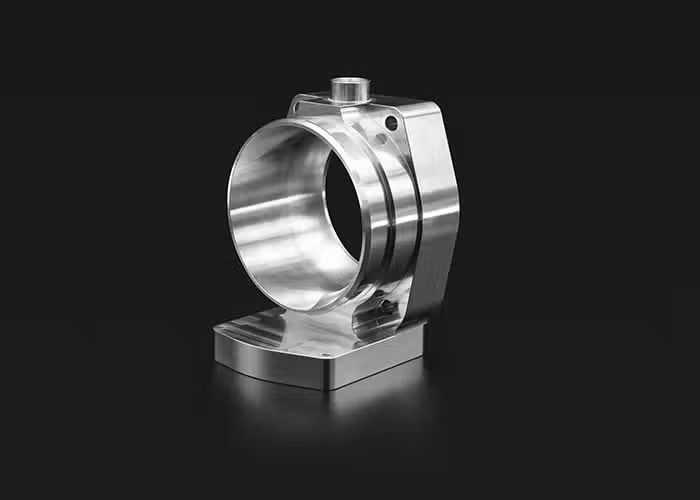

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Design Considerations

- Avoid complex geometries: Complex geometries may result in uneven coating or difficulty covering certain areas. For example, sharp edges and corners may require additional processing to ensure uniform coating

- Drainage and venting design: Parts should be designed to facilitate drainage and venting to avoid bubbles or liquid retention during the coating process, resulting in coating defects. For example, design appropriate holes or notches on the parts so that the liquid can drain smoothly

- Coating time: The length of coating time will affect the thickness and quality of the coating and needs to be optimized according to specific process requirements