Polishing

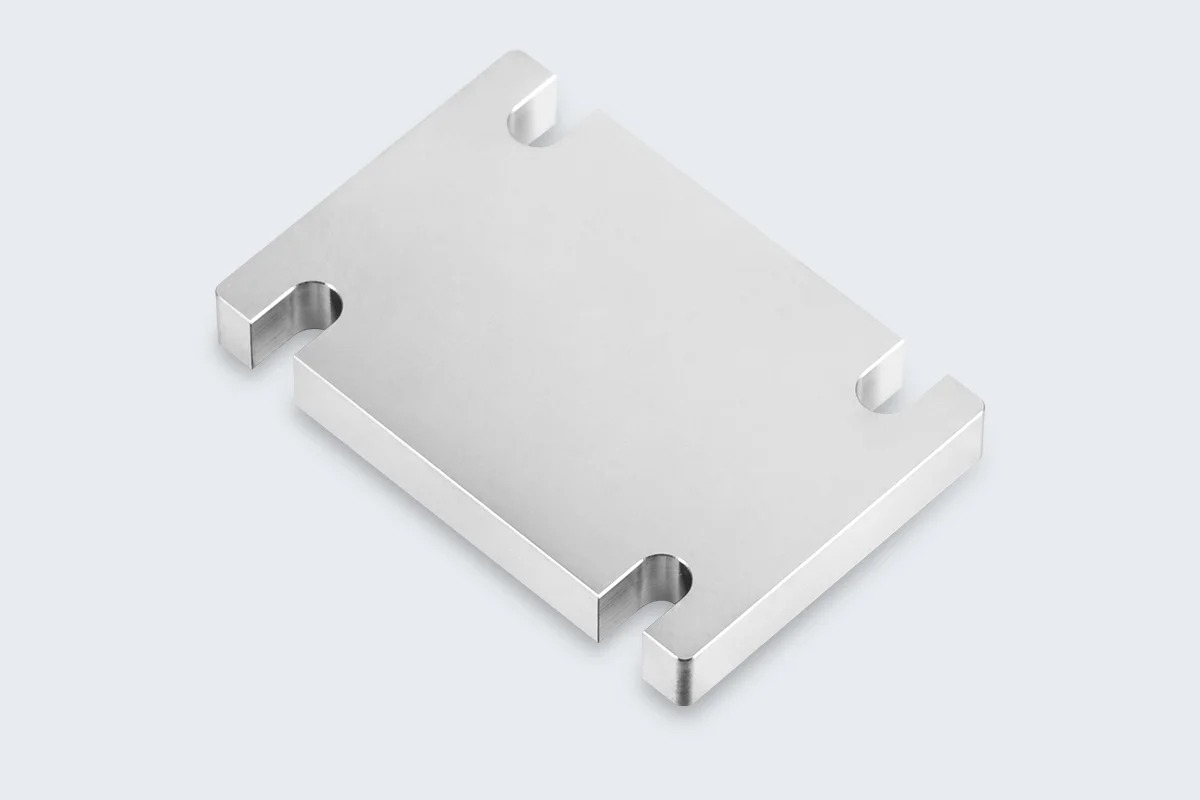

there are often tool marks on the surface of as machined parts, and the surface roughness is usually not very good, typically Ra1.6μm to 3.2μm.

Fortunately, we can improve the surface roughness to Ra 0.4μm to 0.8μm through manual polishing or mirror polishing.

If 0.4μm to 0.8μm still fail to meet your needs, you can opt for mirror polishing.

Mirror polishing is a high-precision process that achieves a mirror-like, smooth surface on parts through mechanical or manual grinding and polishing. This surface finishing not only enhances the appearance of parts but also improves their physical properties, such as reducing friction and wear, and increasing corrosion resistance.

Materials for Polishing

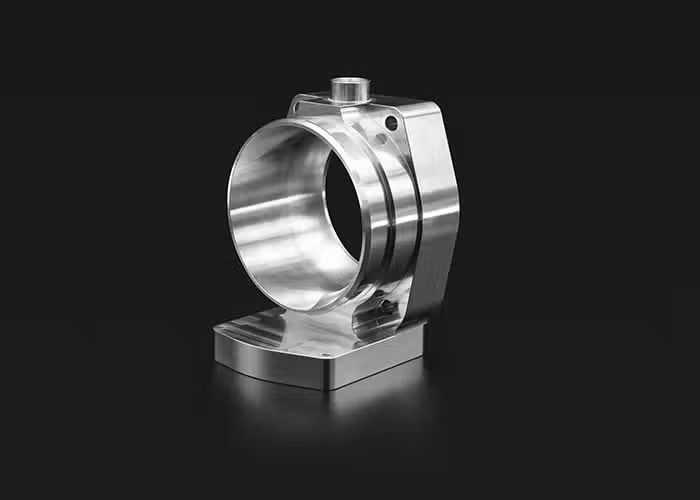

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

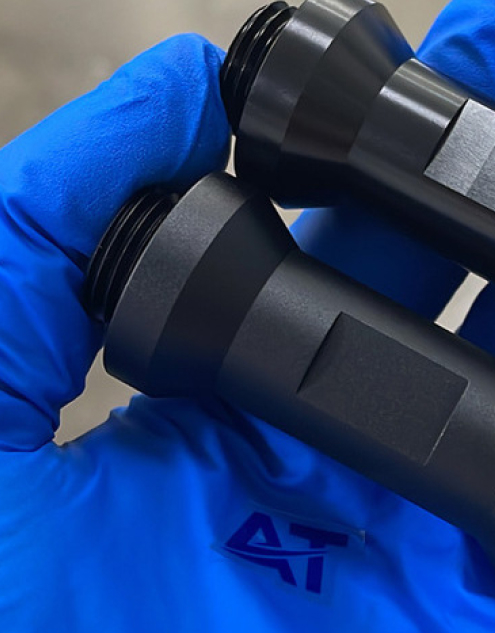

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Design Considerations

- The type of material (such as steel, aluminum, copper, etc.), thickness, strength and its inherent characteristics (such as hardness, corrosion resistance) will affect the choice and effect of the polishing method.

- Determine the required surface roughness level according to the application requirements of the product, such as mirror polishing, smooth polishing, use different coarse and fine abrasives and polishing tools for physical friction polishing.

- Some materials may be more susceptible to scratches or deformation during the polishing process.

- Cool and lubricate the components in time during the polishing process to reduce friction and heat generation and prevent overheating of the parts and thermal damage of the compound, and avoid using water to cool certain metals, such as magnesium alloys, as they may cause fire

- Use jigs or special fixtures to ensure that the component is firmly fixed to the workbench to prevent movement or vibration during polishing.