Strengths

- Corrosion resistance, especially seawater

- Castability

- Strength

- Wear resistance

- Beauty

- Good electrical and thermal conductivity

- Recyclability

Weaknesses

- Cost: Cost more than some other alloys, especially when the tin content is high.

- Weight: Has a higher density, which can make it heavier than other alloys in some applications.

- Difficulty in machining: Machining bronze may require special tools and techniques.

- Susceptibility to corrosion: Corrode in certain environments, especially when the tin content is high.

- Magnetism: Can be magnetic, which can be a problem in some applications.

Application

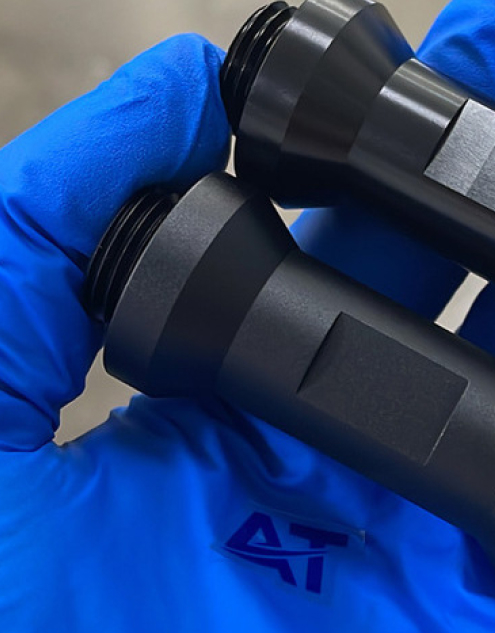

- Marine industry: Manufacture propellers, marine accessories, etc.

- Electrical industry: Manufacture electrical components such as switches, contacts, etc.

- Valves and pipe fittings: Manufacturing valves and pipe fittings.

Available finishing

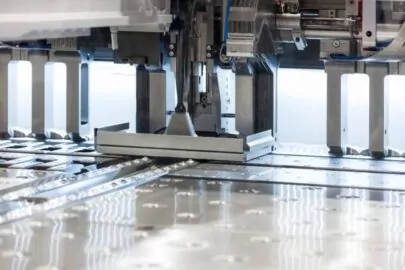

to CNC Machining

Why Choose Our Custom CNC

Machining Service

1-to-1 Quote Analysis

Just upload your 2D or 3D design and you will get quote feedback in 24 hours. Our specialized engineers will analyze your design to avoid misunderstanding in your 2D or 3D design, communicate with you and offer an affordable price.

Fast Lead Time

The introduce of advanced 5 axis CNC machining and professional quoters ensure the fast lead time. We set the priority for the arrangement of the order according to the requirements and order complexity.

High-Quality Production Parts

The responsible and rigorous attitude towards materials, machining technique, surface finishing and CMM testing guarantee the consistent quality from prototyping to production parts. We won’t bother to check the parts quality before delivery.

Instant Communication

For the sake of your benefits, every customer will have technical support to get in touch with us from quotation to delivery. You will get instant feedback for any question until it’s confirmed that you receive the satisfied parts.