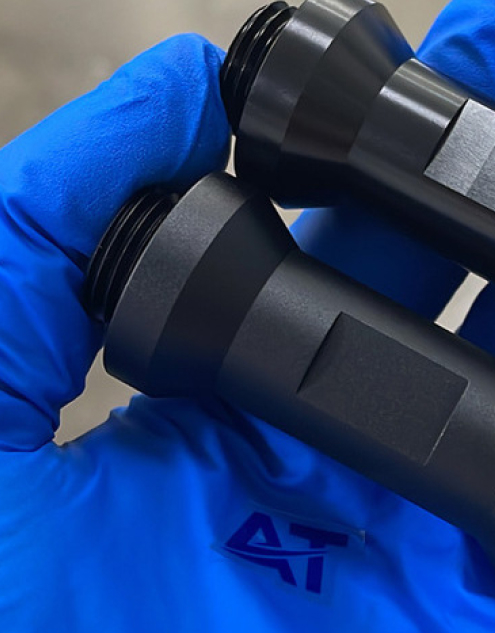

Nitriding

Nitriding is a heat treatment process that creates a hardened layer by diffusing nitrogen into the metal surface.

This process is mainly used for steel, but it can also be applied to metals such as titanium, aluminum and molybdenum.

Nitriding can increase the hardness of the metal surface and enhance wear resistance, galling resistance and corrosion resistance. In addition, nitriding can also increase the fatigue life of the metal.

Materials for

Nitriding

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Design Considerations

- Material Selection: Nitriding is most effective on steels that contain sufficient amounts of alloying elements like chromium, molybdenum, and aluminum, which form hard nitrides.

- Geometry: The geometry of the part can affect the nitriding process. Sharp corners and thin sections can lead to stress concentration and potential cracking.

- Processing Time: Longer times can lead to a deeper nitride layer but may also cause distortion or dimensional changes.

- Dimensional Control: Nitriding can cause dimensional changes due to the diffusion process. These changes must be accounted for in the design to ensure parts fit within tolerances.

- Stress Relief: Since nitriding can introduce residual stresses, stress-relief treatments may be necessary to prevent warping or cracking.

- Corrosion Resistance: While nitriding can improve wear resistance, it may affect the corrosion resistance of the material. This needs to be considered, especially for parts exposed to corrosive environments.