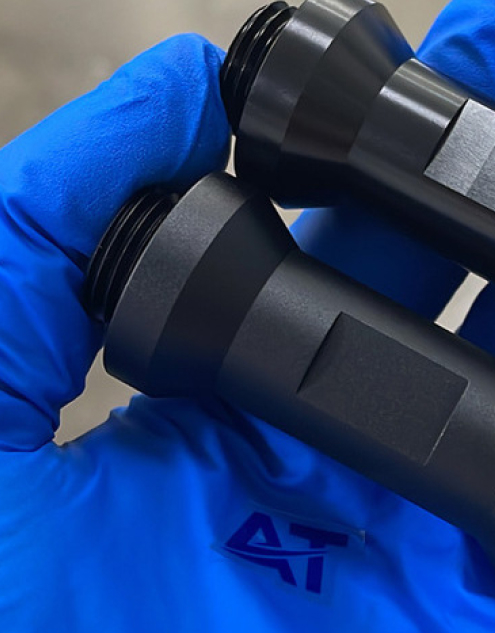

Quench-Polish-Quench

QPQ is a metal surface finishing that improves the hardness, strength, durability, high wear resistance, corrosion resistance and surface finish of metal components through three main steps: quenching – polishing – quenching.

Quenching: reduce the plasticity of metal and increase its brittleness, but it can also significantly increase its hardness and wear resistance.

Polishing: performed after quenching to remove roughness and imperfections from the metal surface and make the surface smoother and glossier.

Second quenching: help stabilize the metal’s microstructure and reduces the risk of deformation and cracks during processing.

Available Materials

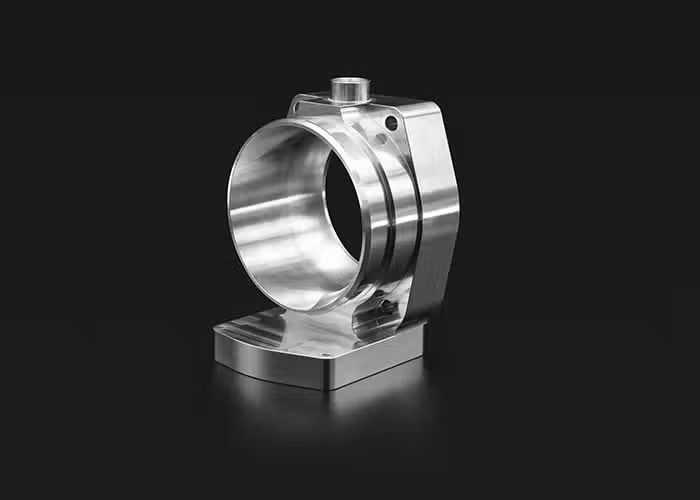

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Steel is a strong, versatile, and durable alloy of iron and carbon. Its applications range from construction materials and structural components to automotive and aerospace components.

Steel is strong and durable High tensile strength Corrosion resistance Heat and fire resistance Easily molded and formed.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Design Considerations

- Control the temperature range (usually 500-570°C) and holding time (30-90 minutes) of the nitrocarburizing stage, which depends on the material type and thickness.

- Gas nitrocarburizing and salt bath nitrocarburizing are two commonly used nitrocarburizing methods. It is necessary to select a suitable method and control the gas flow and concentration.

- The material compatibility and substrate limitations of QPQ coatings need to be considered. Some materials may not be suitable for QPQ coatings, and some substrates may require additional pre- or post-treatment procedures.

- QPQ coatings can enhance the properties of materials, making them stronger and more resistant to corrosion, wear and fatigue. The hardness, wear resistance, corrosion resistance, fatigue strength and friction lubricity of the coating need to be considered.