Clear PC

Clear PC is a surface finishing technology for polycarbonate (PC) materials. Clear PC relies on the fumigation of the gas generated by chloroform after being heated by water evaporation (water isolation) until the PC surface is polished and smooth.

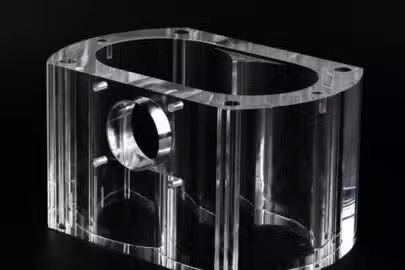

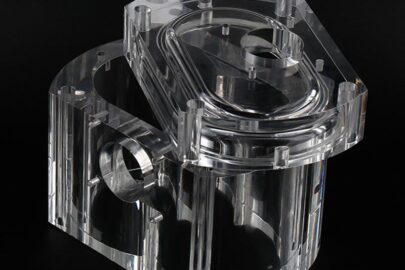

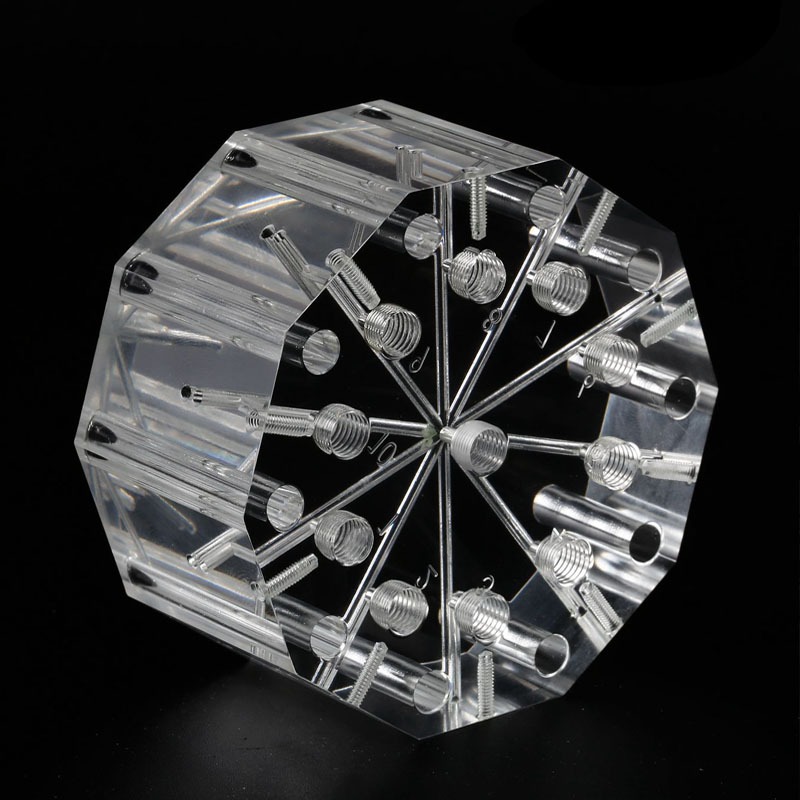

The surface gloss of parts becomes more beautiful, changing from matte texture to glossy texture, with smooth touch and higher appearance after chemical fumigation.

The surface smoothness is significantly improved. The degree and effect of the treatment can be improved by adjusting the fumigation process parameters to make the surface denser and smoother.

The mechanical properties are improved. After polishing, thanks to the reduction of surface roughness of the parts and the disappearance of cracking points, the elongation at break is significantly improved.

Design Considerations

- Control processing temperature: The processing temperature of PC materials needs to be moderate. Too high or too low will affect transparency. Maintain stable temperature and pressure during processing.

- Control screw speed: Reasonable screw speed can ensure that PC materials are fully plasticized during processing, eliminate bubbles and impurities, and enhance transparency.

- Mold design: The mold surface should be smooth and flawless to ensure that there are no marks and spots on the surface of the product.

- Remove moisture and volatiles: The surface of polycarbonate material is inert, which is not conducive to the complete wetting of the coating and the bonding of the interfacial chemical bonds. Therefore, the surface of polycarbonate transparent parts should be activated before coating to improve the leveling of the coating and the adhesion of the coating. PC materials may contain moisture and volatiles, which will affect their transparency. Therefore, they must be fully dried before processing.