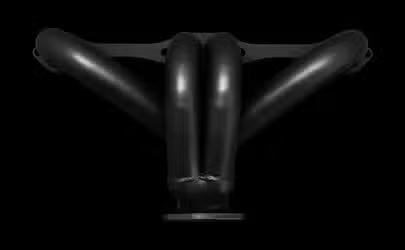

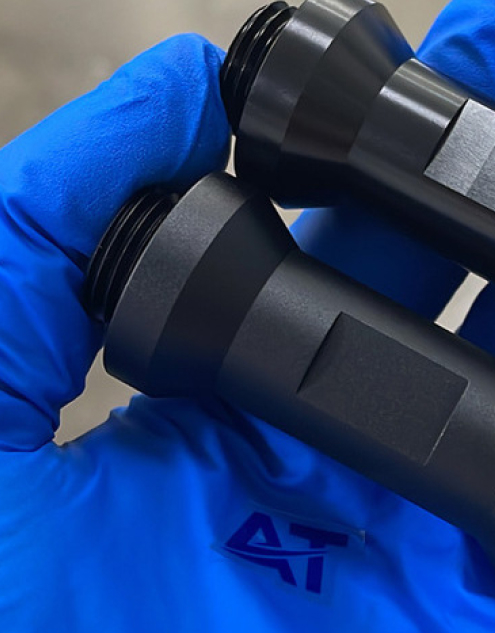

Ceramic Coating

Ceramic coating is a surface finishing technology that applies ceramic materials on the surface of a substrate, mainly used to improve the performance of the substrate, such as wear resistance, heat resistance, chemical corrosion resistance, etc.

Ceramic coatings are widely used in aerospace, automobiles, industrial equipment, medical equipment and other fields.

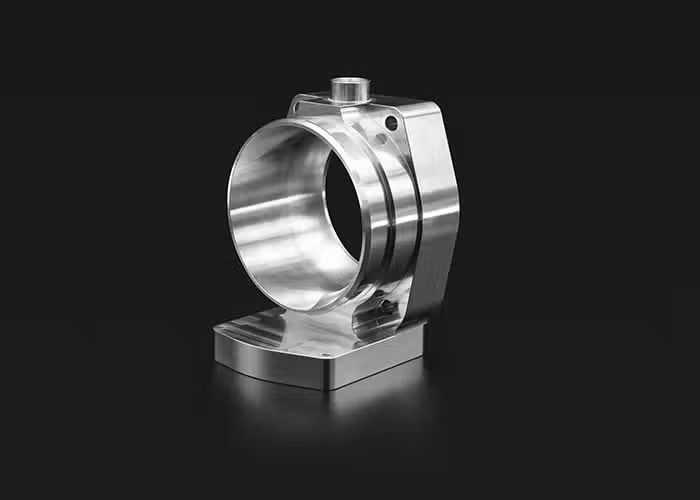

Available Materials

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Due to the low mechanical strength of pure magnesium, magnesium alloys are mainly used. Magnesium alloy has low density but high strength and good rigidity. Good toughness and strong shock absorption. Low heat capacity, fast solidification speed, and good die-casting performance.

Design Considerations

- Thermal Expansion Coefficient (CTE): The CTE of the substrate and the ceramic coating should be as close as possible to minimize thermal stresses during temperature changes. For example, using a substrate with a similar CTE to the ceramic can prevent cracking or delamination.

- Crack Propagation: Thicker coatings may be more prone to crack propagation, so a balance must be struck between performance and durability.

- Material Selection: Different ceramic materials offer varying levels of performance in terms of hardness, thermal conductivity, and chemical resistance. For instance, alumina is commonly used for its excellent wear resistance, while zirconia is known for its thermal shock resistance.

- Composite Coatings: In some cases, using a composite coating with multiple layers can provide enhanced performance. For example, a base layer might provide adhesion and a top layer might offer superior wear resistance.