Poultry Feed Pellet Machine

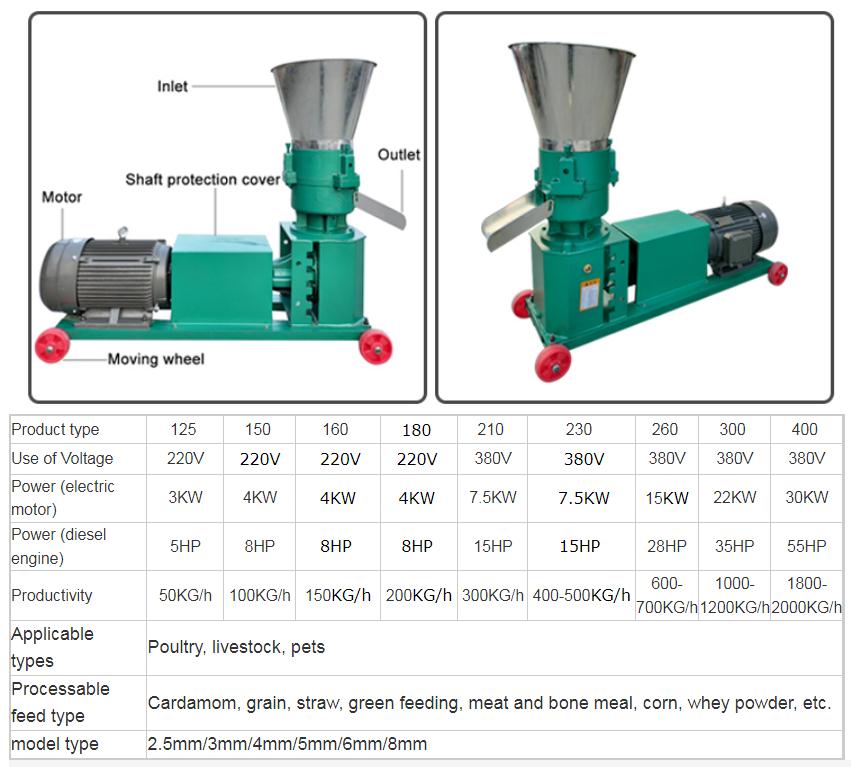

Feed pellet machine (also known as: pellet feed machine, feed pellet machine, pellet feed molding machine) is a feed pelletizing equipment. It is a feed processing machine that uses corn, soybean meal, straw, grass, rice husk, etc. as raw materials, crushes the raw materials and directly presses them into pellets.

Feed pellet machines are divided into ring-die feed pellet machines, flat-die feed pellet machines, and roller feed pellet machines; according to use, they can be divided into: small household pellet feed machines, poultry feed pellet machines, small poultry feed pellet machines, fish feed pellet machines machine, rabbit feed pellet machine, pig feed pellet machine, straw feed pellet machine; according to production, it can be divided into: straw feed pellet machine, wheat bran feed pellet machine, soybean meal feed pellet machine, corn straw feed pellet machine, sawdust feed pellet machine wait. Various feed pellet machines are classified according to their appearance and production methods.

The role of pellet mills in farms

How to reduce feed costs while meeting the nutritional needs of various livestock and poultry has become an urgent issue for farmers and the feed industry. Straw biochemical protein feed technology is to use crop straws through crushing, fermentation, granulation and other technical measures to soften the lignin and degrade crude protein, crude fiber, crude fat, etc. into substances that are easy for livestock to digest and absorb. At the same time, fermentation also produces A large amount of bacterial protein becomes soft, ripe, and sweet after fermentation. The pelleting increases the palatability of poultry and livestock. The average levels of crude protein and amino acids will increase by 40.6% and 95.8%, including arginine, cystine, and histamine. The acid level has also been greatly increased, the sugar and fat content have increased, and vitamins and growth factors such as B, D, and E have been produced, which are then mixed with other raw materials to prepare full-price feed and then pressed into nutrient-rich feed pellets by a pellet feed machine, making the livestock more nutritious. Feed intake increases significantly and growth accelerates. It not only reduces grain input (each ton of straw feed is equivalent to the nutritional value of 270 kilograms of grain feed), saves feed costs, but also increases farmers' income.

Main features of pellet machine

1. Simple structure, wide adaptability, small footprint and low noise.

2. Powdered feed and grass meal can be granulated without adding a little liquid, so the moisture content of the pellet feed is basically the moisture content of the material before granulation, which is more convenient for storage.

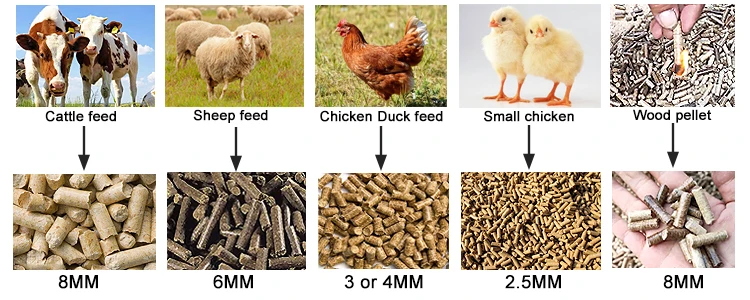

3. Chicken, duck, fish, etc. can obtain higher economic benefits than mixed powder feed. 4. Dry material processing, the feed particles produced have high hardness, smooth surface and internal ripening, which can improve the digestion and absorption of nutrients.

5. The granule formation process can denature the pancreatic enzyme resistance factors in cereals and beans, reduce adverse effects on digestion, kill various parasite eggs and other pathogenic microorganisms, and reduce various parasites and digestive system diseases.

The press roller and grinding disc are made of chromium manganese steel, which is 10 to 20 times the wear-resisting degree of ordinary steel after high-temperature quenching.

The feed pellet processed by feed pellet machine are smooth, uniform and moderate hardness.Pellet size can be achieved by changing different grinding disc.

Note: if you are looking for feed pellet machine driven by diesel engine, gasoline engine or PTO, pls see small feed mill for sale, or send us an equiry.

Before-sale services

1. 24 hours online, Your inquiry will be reply quickly.

2. Help you choose the most suitable machine

3. Introduce details of the machine for you with pictures or video.

Sales service

1. Customized machine according to your request.

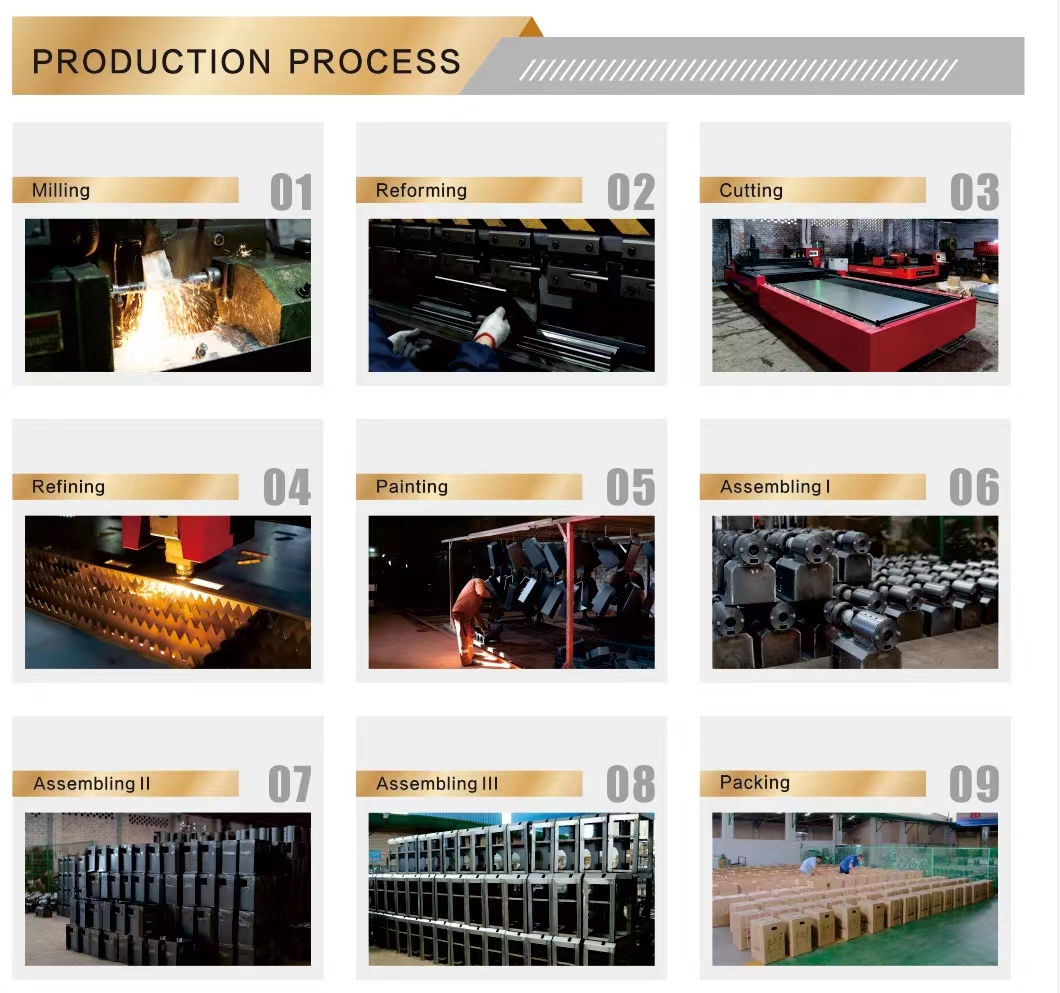

2. Test and inspect every machine with strict quality control.

3.Packing with standard export wooden box after you confirm the machine

After-sales service

1. Offer the professional engineer help you to use the machine.

2. Offer technical support and professional engineer help you solve problems while using it.

3. Quality guarantee for two years. Free repair for quality problem during these years.