Wood chipper for sale

The wood chip crusher consists of a chip device, a crushing device and a fan. This machine is a chip crushing equipment that can crush rod-shaped materials with a diameter of 5-20 cm and a plate with a width of 20 cm. This machine has the characteristics of small size, high output, and can also be used for mobile operations. Used in small charcoal plants and feed processing industries.

working principle of wood chipper

The wood chip crusher uses blade cutting and high-speed airflow impact and collision dual crushing functions in one, and can complete the micro material sorting and processing process at the same time. During the cutting and crushing process of the blade, the rotor generates high-speed airflow, which rotates in the cutting direction of the blade. The material is accelerated in the airflow, and the repeated impact causes the material to be double crushed at the same time, accelerating the crushing rate of the material.

Structural principles of wood chipper

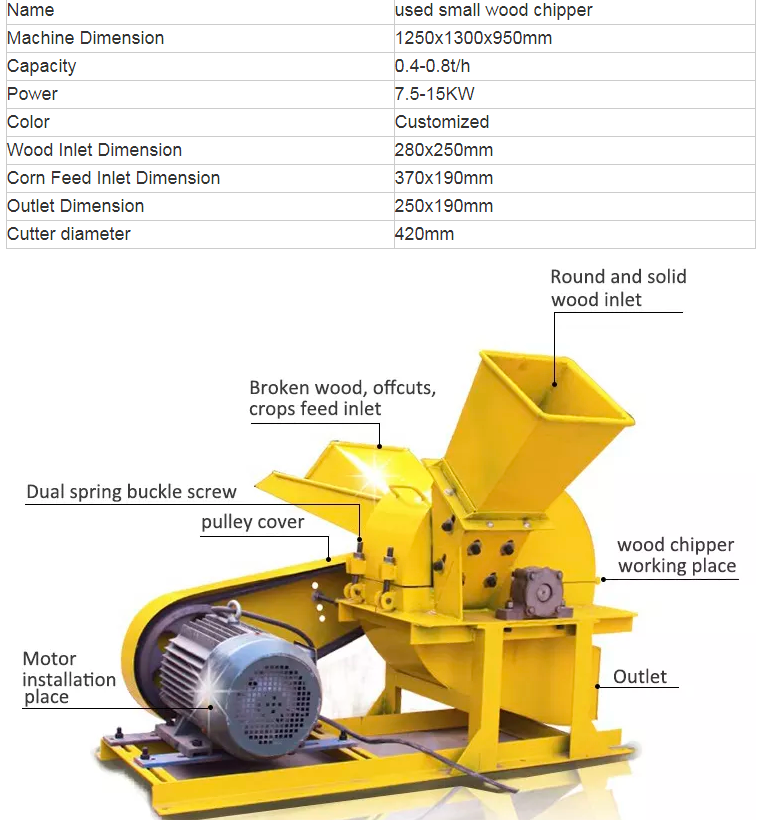

The main machine of the wood chip crusher is composed of three parts: the rotor, the upper body and the lower body. The crushing chamber adopts multi-stage crushing process and fine crushing principle device, which is characterized by large working impact force, high production efficiency and strong fine crushing ability.

The complete wood chip crusher machine consists of a host machine, a fan, an analyzer, a powder collector, a dust collector and other parts. Each component has a compact structure and reasonable layout. Its outstanding features are easy operation, safe use, good sealing and low noise.

Wood chipper use

The wood chip crusher is a new type of wood chip machine, wood chip crusher, and wood chip pellet machine that is ideal for the front-end production of wood powder. It can process wood, branches and other raw materials into wood chips at one time. It has the advantages of low investment, low energy consumption, high productivity, good economic benefits, and easy use and maintenance. The whole set of equipment is driven by only one motor. It has a simple structure, compact layout, low price, stable operation, low energy consumption, high output, good quality of finished wood chip machine and low processing cost. It can also be used for cutting fibrous stalk-like materials such as bamboo, thatch, corn stalks, and sorghum stalks. The sawdust crusher can also be used for raw material production of particle board and sawdust board high-density board.

Wood chip machine, chip machine, wood chip crusher can process pine, miscellaneous wood, poplar, fir, and original bamboo. Because the machine has a compact structure, small footprint, good chipping quality, low power consumption, and is suitable for flow It is widely used in the material preparation section of small and medium-sized particleboard and fiberboard production enterprises, and can also be used by self-employed individuals to produce commercial wood chips.