Brushing

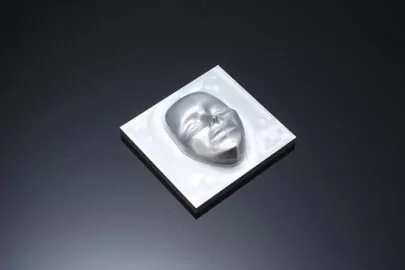

Brushing, as a surface finishing, mainly refers to the process of mechanically creating continuous, parallel fine lines or textures on the metal surface.

Brushing not only enhances the aesthetics of the metal surface, but also improves the touch and anti-slip performance by hiding small scratches.

Brushing can produce a variety of texture effects, such as straight lines, random lines, threads, waves and swirls. These textures not only have decorative effects, but also provide functional benefits such as corrosion resistance and hiding mechanical marks and mold defects.

Available Materials for Brushing

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

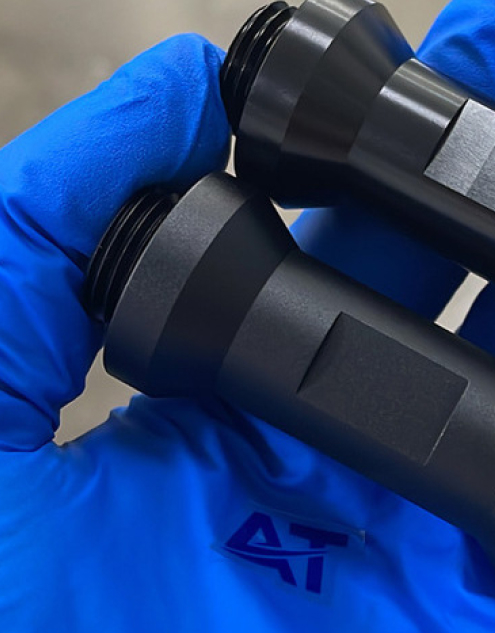

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Design Considerations

- The desired finish (e.g., matte, semi-gloss, high-gloss) will influence the type of brush and the brushing technique used.

- The brush material should be compatible with the material being brushed to avoid chemical reactions that could damage the finish.

- The size and shape of the brush should be appropriate for the surface area and contours of the object being brushed. Smaller brushes may be needed for detailed work, while larger brushes can cover larger areas more efficiently.

- The amount of pressure applied by the brush can affect the finish. Too much pressure can lead to material damage, while too little may not achieve the desired effect.

- The speed at which the brush moves across the material must be within an optimal range to achieve the best results. Too slow, and the brush may not remove any material; too fast, and it could damage the material or result in improper processing.