Chromate

Chromate surface finishing is mainly used to improve the corrosion resistance and adhesion of metals, making it more suitable for subsequent processes such as painting and bonding. It immerses the metal in a solution containing chromate to form a thin chromate conversion film. This film can effectively block the intrusion of corrosive media, thereby extending the service life of the metal.

Chromate surface finishing is widely used in the automotive, aviation, electronics and other industries to treat light metals such as aluminum, magnesium, and zinc.

However, due to the certain toxicity of chromate compounds, safety regulations need to be strictly followed when using them to avoid harm to the environment and human health. In recent years, with the improvement of environmental protection requirements, some alternative environmentally friendly surface treatment technologies have also been continuously developed.

Available Materials

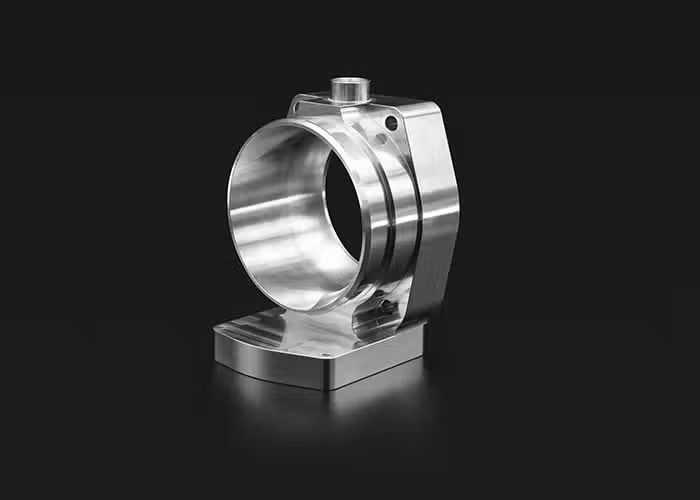

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Due to the low mechanical strength of pure magnesium, magnesium alloys are mainly used. Magnesium alloy has low density but high strength and good rigidity. Good toughness and strong shock absorption. Low heat capacity, fast solidification speed, and good die-casting performance.

Design Considerations

- Roughness requirements: Before chromate treatment, the surface roughness of the parts should be controlled within a certain range, usually 4 to 10 micro inches RMS (0.102 to 0.254 microns Ra) . A surface that is too rough will affect the uniformity and adhesion of the chromate film, while a surface that is too smooth will be detrimental to the adhesion of the coating.

- Surface finishing: Before chromate treatment, the surface of the parts usually needs to be pre-treated, such as sandblasting, polishing, etc., to remove impurities such as oil stains and scale on the surface, and to adjust the surface roughness. For example, aluminum alloy parts can be sandblasted to improve surface roughness before chromate treatment, thereby enhancing the adhesion of the chromate film.

- Conductivity: Chromate treatment does not significantly affect the conductivity of metals. For parts that need to maintain good conductivity, such as electronic components, electrical connections, etc., chromate treatment is a suitable option