Laser Engraving

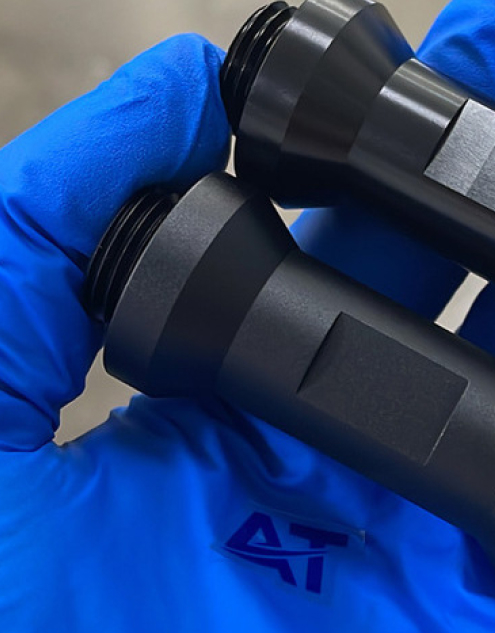

Laser Engraving is a surface finishing that uses a high-energy laser beam to mark or engrave on the surface of a material. Laser engraving generates heat on the surface of the material through a focused laser beam, causing the material to partially melt or vaporize, thereby forming a permanent mark or pattern on the surface of the material.

Unlike traditional mechanical engraving, laser engraving is a non-contact processing method that does not cause mechanical damage to the surface of the material.

Applicable to a variety of materials, including metal, plastic, glass, wood, etc. Common laser sources include CO2 lasers and fiber lasers. CO2 lasers are suitable for engraving non-metallic materials (such as wood, plastic, glass, etc.), while fiber lasers are suitable for engraving metal materials.

Available Materials For Laser Engraving

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Steel is a strong, versatile, and durable alloy of iron and carbon. Its applications range from construction materials and structural components to automotive and aerospace components.

Steel is strong and durable High tensile strength Corrosion resistance Heat and fire resistance Easily molded and formed.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Design Considerations

- High contrast between the engraved area and the surrounding material is key for visibility.

- High-resolution designs are better suited for laser engraving. Fine details can be achieved, but very small or complex designs may need adjustments to ensure they are visible and not lost in the engraving process.

- Line thickness should be adjusted to create depth and emphasis.

- Test engraving settings before final engraving to determine optimal settings.

- Account for material thickness and material properties when designing for engraving.

- Vector graphics are preferred over raster images for laser engraving because they can be scaled without loss of quality. If using raster images, make sure they are high resolution.