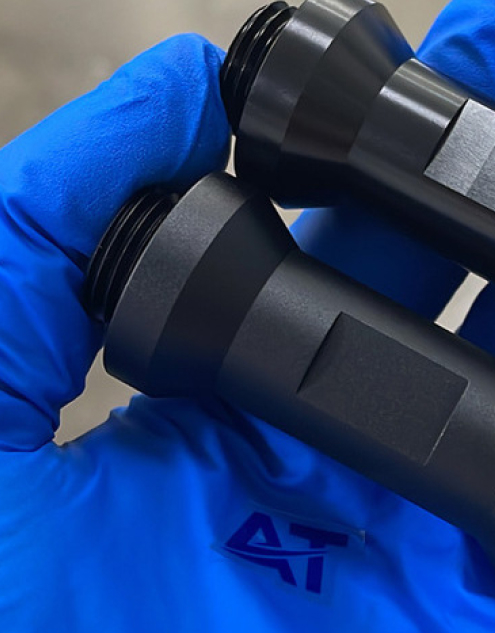

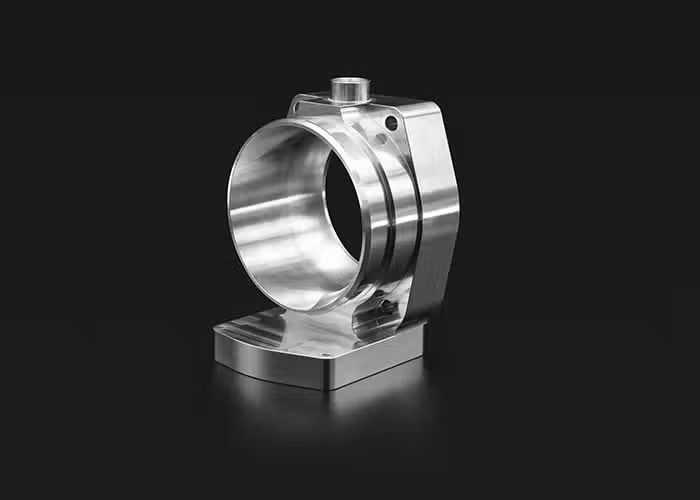

Deburring

Deburring is a very important step in the metalworking process, which involves removing unwanted projections, sharp edges or small raised parts (i.e. burrs) produced during the manufacturing process of metal parts. These burrs are usually formed during mechanical processes such as casting, forging, machining, or welding, etc.

Precision: Burrs or protrusions can interfere with precise assembly.

Aesthetics: Defects make a part look unfinished or sub-par. Deburring provides a polished, professional look that enhances the overall presentation of the product.

Safety: Sharp edges left after machining can cause cuts or injuries during handling. Therefore, removing these defects ensures that the part is safe to use.

Available Materials

High machinability and ductility, good strength-to-weight ratio. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Steel is a strong, versatile, and durable alloy of iron and carbon. Its applications range from construction materials and structural components to automotive and aerospace components.

Steel is strong and durable High tensile strength Corrosion resistance Heat and fire resistance Easily molded and formed.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Iron is an indispensable metal in the industrial sector. Iron is alloyed with a small amount of carbon – steel, which is not easily demagnetized after magnetization and is an excellent hard magnetic material, as well as an important industrial material, and is also used as the main raw material for artificial magnetism.

Due to the low mechanical strength of pure magnesium, magnesium alloys are mainly used. Magnesium alloy has low density but high strength and good rigidity. Good toughness and strong shock absorption. Low heat capacity, fast solidification speed, and good die-casting performance.

Design Considerations

- Choose materials that are less prone to burr formation. Some materials are more resistant to burrs due to their hardness or grain structure.

- Design parts with tolerances that account for the potential presence of burrs. This can help ensure that parts will still fit and function even if burrs are present.

- Design parts with larger edge radii to reduce the stress concentration that can lead to burrs.

- Design parts in a way that minimizes the need for sharp corners or edges that are difficult to deburr.

- Consider the machining process when designing parts. Some processes are more prone to burrs than others. For example, turning and milling can produce burrs, while casting or forging can minimize them.

- Design tools and dies to minimize burr formation. This might include using tools with rounded edges or designing them to break off burrs during the cutting process.

- Ensure that the design does not create burrs that could be a safety hazard, such as sharp edges that could cut or injure workers.