Silk Screen

Silk screen is a printing technology that uses a silk screen as a base, produces a silk screen with images and texts through a photosensitive platemaking method, and then uses the holes in the silk screen to print ink onto the substrate.

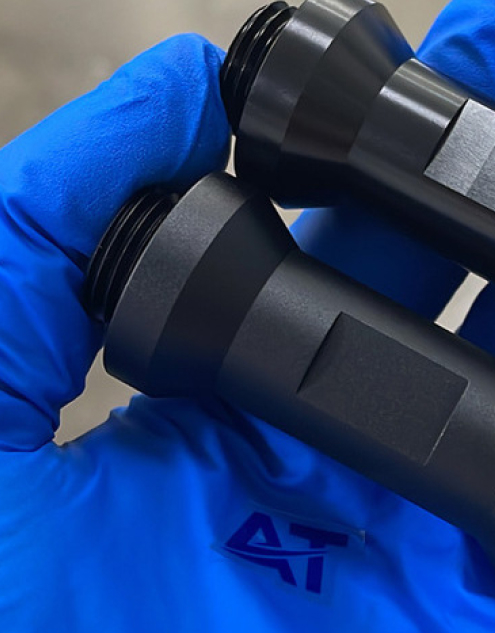

Wide range of applications: Screen printing can be applied to the surfaces of various materials, including paper, plastic, metal, glass, ceramics, textiles, etc.

Various substrate shapes: It is not only suitable for flat substrates, but also for curved and irregular-shaped substrates, such as bottles, spheres, etc.

Available Materials For Silk Screen

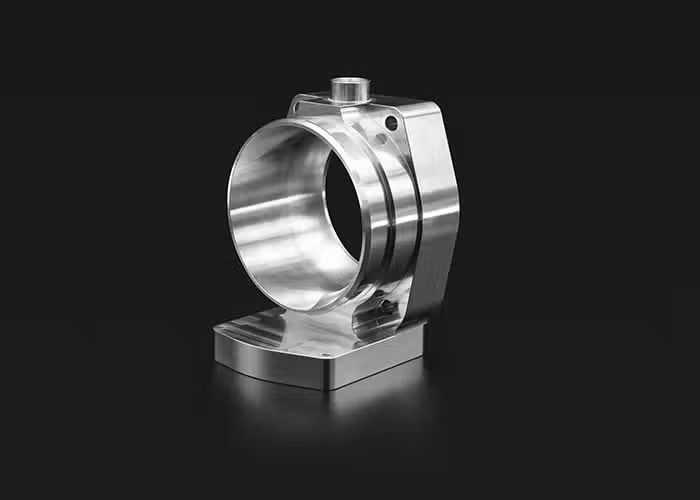

High machinability and ductility. Aluminum alloys have good strength-to-weight ratio, high thermal and electrical conductivity, low density and natural corrosion resistance.

Steel is a strong, versatile, and durable alloy of iron and carbon. Steel is strong and durable. High tensile strength, corrosion resistance heat and fire resistance, easily molded and formed. Its applications range from construction materials and structural components to automotive and aerospace components.

Stainless steel alloys have high strength, ductility, wear and corrosion resistance. They can be easily welded, machined and polished. The hardness and the cost of stainless steel is higher than that of aluminum alloy.

Highly resistant to seawater corrosion. The material’s mechanical properties are inferior to many other machinable metals, making it best for low-stress components produced by CNC machining.

Brass is mechanically stronger and lower-friction metal properties make CNC machining brass ideal for mechanical applications that also require corrosion resistance such as those encountered in the marine industry.

Few metals have the electric conductivity that copper has when it comes to CNC milling materials. The material’s high corrosion resistance aids in preventing rust, and its thermal conductivity features facilitate CNC machining shaping.

Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed.

Titanium is an advanced material with excellent corrosion resistance, biocompatibility, and strength-to-weight characteristics. This unique range of properties makes it an ideal choice for many of the engineering challenges faced by the medical, energy, chemical processing, and aerospace industries.

Due to the low mechanical strength of pure magnesium, magnesium alloys are mainly used. Magnesium alloy has low density but high strength and good rigidity. Good toughness and strong shock absorption. Low heat capacity, fast solidification speed, and good die-casting performance.

Design Considerations

- Choose the appropriate ink according to the substrate and application requirements. For example, high-temperature resistant ink is suitable for parts that require high-temperature treatment, and chemical corrosion-resistant ink is suitable for chemical environments. Choose ink with high color contrast with the substrate to ensure that it can still be clearly identified under different lighting conditions.

- Choose the appropriate screen mesh according to the complexity and detail requirements of the design. High-mesh screens are suitable for fine patterns, and low-mesh screens are suitable for large-area printing.

- Ensure the alignment accuracy during the printing process to avoid pattern offset or overlap, especially when printing in multiple colors.

- Ensure that the silk-screen text is clear and readable, and choose the appropriate font and size. For electronic components such as PCBs, the ratio of font height to width is usually required to be ≥6:1.